OKUTANI Ltd. Hall 8 / B38

Exhibitor Profile

OKUTANI, a Japanese company with over 129 years of history. Innovating at the same time preserving traditional craft ship spirits is our strength.

This year in FILTECH 2024 we are introducing several updates, focusing on advanced perforation technologies and materials.

Key highlights include:

- SUPER PUNCHING/ULTRA SUPER PUNCHING: The reputation of our business, technology of punching holes smaller than the thickness of the metal plate; or the hole centers are thinner than the material thickness. Such products used in industries like nuclear energy and water treatment by offering high pressure resistance, durability, and weight reduction.

- X-OPEN AREA Punching: This technique achieves an 80-90% open area of a perforated metal, significantly improving pressure resistance, durability, and weight reduction, making it ideal for applications like air filters and audio speaker covers.

- Perforated CFRTP: In collaboration with Toray. Which is lighter, stronger, and more suitable for automotive and aerospace applications compared to traditional carbon fiber-reinforced plastics.

- Expanded CFRTP: This composite material offers excellent formability, thermal conductivity, and recyclability, making it suitable for a wide range of uses, including interior design and protective covers.

- Okutani Duplex Stainless Sanitary Strainer: Two combined advantages make the ODS Strainer a brilliant invention. The materials and the technology! Adopting Okutani’s advanced Super Punching technology and laser drilling technology to enable a wide range of hole diameters from 0.035mm to 1.00mm. Using Duplex stainless steel (SUS821L1 (NSSC2120®), SUS329J1 equivalent (NSSC®2351), which offers almost twice the strength and wear resistance of conventional products, with enhanced corrosion resistance and high-precision filtration capabilities.

Products / Markets

Product Index

- Abwasserfilter

- Filtergehäuse

- Filterzentrifugen

- Gewebelaminate, Metal

- Korbfilter

- Luftfiltermedien

- Perforierte Metalle

- Scheibenfilter

- Siebe

- Tropfenabscheider

- Ölfilter

Market Scope

- Abwasserwirtschaft

- Chemische Industrie

- Energieerzeugung,-versorgung

- Filtrations- und Separationsindustrie

- Kunststoffverarbeitende Industrie

- Lebensmittel-,Getränkeindustrie

- Luft- und Raumfahrtindustrie

Product Index

- Air Filter Media

- Basket Filters (Strainers)

- Demisters

- Disc Filters

- Filter Centrifuges

- Filter Housings

- Oil Filters

- Perforated Metals

- Sieves

- Waste Water Filters

- Wire Mesh Laminates, metal

Market Scope

- Aerospace Industry

- Chemical Industries

- Energy, Energy Supply

- Filtration and Separation Industry

- Food, Beverage Industry

- Plastic Industry

- Waste Water Treatment

Product Index

- 废水过滤器

- 滤壳

- 滤油器

- 盘式过滤器

- 离心式过滤器

- 空气过滤器介质

- 穿孔金属板

- 筛

- 篮式过滤器

- 金属网层板

- 除雾器

Market Scope

- 化学工业

- 塑料工业

- 废水处理

- 能源、能源供应

- 航空航天业

- 过滤与分离工业

- 食品、饮料工业

Product Index

- تصفية العلب

- رقائق الشبك المعدني

- فلاتر السلة

- فلاتر زيوت

- فلاتر قرصية

- فلاتر ماء التصريف

- قلاتر الطرد المركزي

- مزيل الضباب / الغشاوة

- معادن مثقبة

- مناخل

- مواد فلاتر الهواء

Market Scope

- الصناعات الغذائية وصناعة المشروبات

- الصناعة الكيماوية

- حماية البيئة

- صناعات الفلترة وفصل المواد

- صناعة البلاستيك

- صناعة الفضاء

- معالجة مياه الصرف

Product Index

- Centrifugeuses à filtre

- Dispositif antibuée

- Filtres pour eau usées

- Filtres à bols

- Filtres à disques

- Filtres à huile

- Fluides pour filtres à air

- Laminés en mailles de fil, métalliques

- Les boîtiers de filtre

- Métaux perforés

- Tamis

Market Scope

- Industrie aérospatiale

- Industrie chimique

- Industrie de filtration et de séparation

- Industrie des matières synthétiques

- Industries alimentaires et des boissons

- Protection de l’environnement

- Traitement des eaux usées

Product Index

- Alloggiamenti filtro

- Centrifughe filtri

- Dispositivi antiappannanti

- Filtri a cestello (filtri)

- Filtri a disco

- Filtri acque reflue

- Filtri olio

- Laminato a rete, metallo

- Metalli perforati

- Mezzi filtranti aria

- Setacci

Market Scope

- Energia, approvvigionamento energetico

- Settore aerospaziale

- Settore alimenti e bevande

- Settore chimico

- Settore filtrazione e separazione

- Settore plastica

- Trattamento acque reflue

Product Index

- Filtry koszowe (sitka)

- Filtry oleju

- Filtry tarczowe

- Filtry ścieków

- Media filtrów powietrza

- Metalowe połączenia wielowarstwowe siatek drucianych

- Obudowy filtrów

- Odmgławiacze

- Perforowane płyty metalowe

- Sita

- Wirówki filtracyjne

Market Scope

- Filtrowanie i separacja

- Oczyszczanie ścieków (waste water)

- Przemysł chemiczny

- Przemysł energetyczny

- Przemysł lotniczy

- Przemysł spożywczy

- Przemysł tworzyw sztucznych

Product Index

- Carcaças de Filtro

- Centrifugadores de filtros

- Crivos

- Desumidificadores

- Filtros de discos

- Filtros de rede

- Filtros de águas residuais

- Filtros de óleo

- Laminados de malha metálica

- Meios de filtro do ar

- Metais perfurados

Market Scope

- Indústria aeroespacial

- Indústria alimentar, de bebidas

- Indústria de filtragem e separação

- Indústria dos plásticos

- Indústrias químicas

- Protecção ambiental

- Tratamento de água de despejo

Product Index

- Антизапотеватели

- Дисковые фильтры

- Корзинчатые фильтры

- Корпуса фильтров

- Масляные фильтры

- Перфорированные металлы

- Сетчатые ламинаты, металл

- Сетчатые фильтры

- Фильтрующие центрифуги

- Фильтрующий материал

- Фильтры сточных вод

Market Scope

- Авиакосмическая промышленность

- Защита окружающей среды

- Отрасль фильтрации и сепарирования

- Очистка сточных вод

- Производство пластмасс

- Производство продуктов питания и напитков

- Химическая промышленность

Product Index

- Aireadores

- Centrífugas de filtro

- Filtro de Viviendas

- Filtros de aceite

- Filtros de agua residual

- Filtros de cesta

- Filtros de disco

- Material laminar de malla de alambre, metal.

- Medios de filtros de aire

- Metales perforados

- Tamices

Market Scope

- Industria aeroespacial

- Industria de la alimentación y las bebidas

- Industria de la filtración y la separación

- Industria de los plásticos

- Industrias químicas

- Protección del medio ambiente

- Tratamiento de aguas residuales

Product Index

- Atıksu Filtreleri

- Buğu Önleyiciler

- Delikli Metaller

- Disk Filtreler

- Elekler

- Filtre Gövdeleri

- Filtre Santrifüjleri

- Hasır Tel Tabakaları, metal

- Hava Filtresi Ortamı

- Sepet Filtreler

- Yağ Filtreleri

Market Scope

- Atıksu Arıtma

- Enerji, Enerji İkmali

- Filtrasyon ve Ayırma Endüstrisi

- Gıda, İçecek Endüstrisi

- Havacılık Endüstrisi

- Kimya Endüstrisi

- Plastik Endüstrisi

Product Index

- 공기 여과재

- 금속 철망 라미네이트

- 데미스터

- 디스크 필터

- 바스켓 필터(스트레이너)

- 오일 필터

- 체

- 타공판

- 폐수 필터

- 필터 원심분리기

- 필터 하우징

Market Scope

- 식음료 산업

- 에너지, 에너지 공급

- 여과 및 분리 산업

- 폐수 처리

- 플라스틱 산업

- 항공우주 산업

- 화학 산업

Product Index

- ふるい

- エアフィルターメディア

- オイルフィルター

- ディスクフィルター

- バスケットフィルター(ストレーナー)

- フィルターハウジング

- フィルター遠心機

- ワイヤーメッシュラミネート

- 剥離器

- 廃水フィルター

- 穴あきメタル

Market Scope

- エネルギー、エネルギー供給

- プラスチック業界

- 化学工業

- 汚水処理

- 濾過および分離技術工業

- 航空宇宙産業

- 食品、飲料業界

What's new

Introducing the latest updates from OKUTANI in 2024, where innovation meets refinement.

With over 129 years of pioneering history, OKUTANI has consistently risen to challenges, striving to surpass customer expectations.

Building upon the solid progress we have made. OKUTANI is excited to unveil updates to our product ability. All seven main products we are sharing with our visitors this year. Including: SUPER PUNCHING, ULTRA SUPER PUNCHING, X-OPEN AREA Punching, Perforated CFRTP, Expanded CFRTP, ODS Punching and Laser Strainer.

SUPER PUNCHING/ ULTRA SUPER PUNCHING

Introducing our revolutionary SUPER PUNCHING/ ULTRA SUPER PUNCHING Technology—a breakthrough in perforation that allows for holes smaller than the metal plate thickness and hole centers thinner than the plate thickness, overcoming what was previously considered impossible in punching.ULTRA SUPER PUNCHING will further improve the utilization rate and productivity of “filtration” filters.

This development offers significant benefits across various industries, particularly in applications requiring high pressure resistance, durability, and reduced weight. Such as nuclear energy, petrochemicals, and water treatment, where effective filtration is critical. The increased plate thickness, combined with precise pore diameters, enhances material strength and longevity, reducing the need for frequent replacements.

But the advantages don’t stop there. This technology is also perfectly suited for filtration systems and vibrating sieve machines, including granulators, granule size selectors, mills, and trommel screens, all of which require high abrasion resistance.

Elevate your operations with the unmatched precision and strength of our Super-Punching Technology..Experience the benefits of our reasonably priced products by visiting our booth at Filtech 2024, and discover how this expertly crafted Japanese technology can transform your most demanding applications.

X-OPEN AREA Punching

Using Super Punching technology to achieve an "80-90%" large opening area which was previously thought impossible. With the definition as followings:

- Round holes have an open area of 70% or more

- Square and hexagonal holes have an open area of 80% or more

- The bone/gap is about half the thickness of the plate (bone/gap is at least 0.5mm)

The technique of high open area perforating enabled the size of bone/gap to be half of the thickness of the plate. This is the realization of ultra-narrow pitch!

X-OPEN AREA Punching is suitable for secondary processing and has the advantage of keeping the surface flat. It offers superior advantages of high pressure-resistance, high durability, long-lasting, and weight reduction, compared to traditional perforating. The applications include air filters, audio speaker cover, housing (reinforcing materials), protecting cover, interior and exterior design materials, ventilating facilities and heat dissipation.

Perforated CFRTP

Okutani Ltd. co-development with Toray Plastics Precision Co.,Ltd. from Toray group.

CFRTP stands for Thermoplastic Carbon Fiber Reinforced Plastic. Unlike the traditional CFRP, which uses thermosetting resin that hardens permanently, CFRTP uses thermoplastics that soften when heated and solidify when cooled.

CFRTP is gaining interest because it has better physical properties. It’s lighter, stronger, and more practical for use in aircraft and high-speed trains compared to traditional CFRP. The reason why CFRTP is expected is for automotive lightweight due to enhanced fuel regulations.

Traditionally, the use of CFRTP has been limited to racing cars and ultra-luxury cars, but with mass production and lower costs, there is a growing expectation that it will be used in mass production vehicles.

Expanded CFRTP

Introducing Expanded CFRTP—a cutting-edge composite material designed for a wide range of applications. Ideal for air filters, housing reinforcements, protective covers, and speaker covers, this material offers lightweighting, formability with existing equipment, and high vibration damping.

With superior sliding properties, high thermal conductivity, and heat resistance, Expanded CFRTP is perfect for both interior and exterior design materials. It also serves as an excellent metal substitute, providing rust prevention, shortened processing times, and recyclability. Whether you need high acoustics or antistatic properties, Expanded CFRTP delivers exceptional performance across diverse applications.

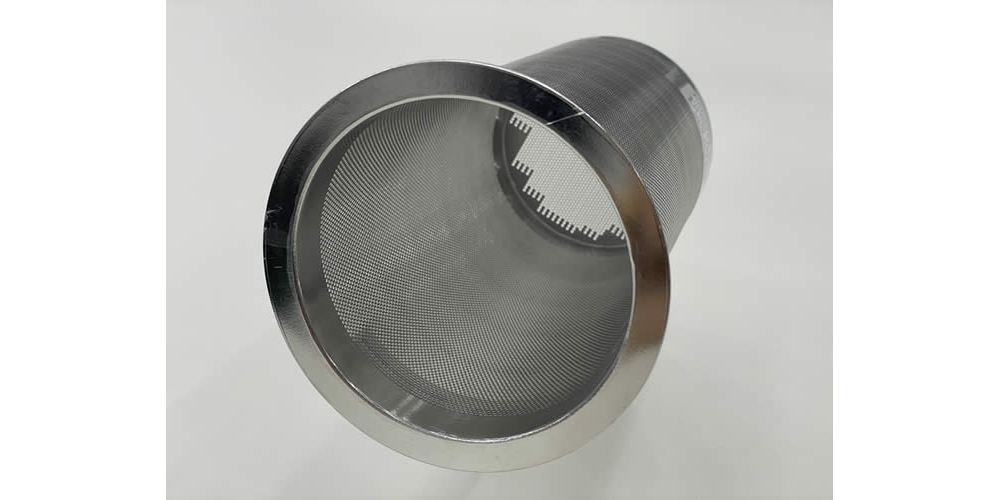

ODS Strainer–Okutani Duplex Stainless Steel Sanitary Strainer

Two combined advantages make the ODS Strainer a brilliant invention. The materials and the technology!

ODS Strainer using Duplex Stainless Steel (SUS821L1 (NSSC2120®), SUS329J1 equivalent (NSSC®2351)) instead of conventional stainless steel (SUS304, SUS316L) as material, which are approximately twice as strong and wear resistant as conventional products. In addition to approximately twice the strength and abrasion resistance of conventional products, it has improved performance such as pitting corrosion resistance, and its price is stable due to its low content of rare metals.

ODS Strainer adopted Okutani’s advanced Super Punching technology and laser drilling technology from our reliable suppliers to enable a wide range of hole diameters from 0.035mm to 1.00mm. Enhancing the products reach the standard of customers– High-precision filtration, not to mention the advantages of perforated and laser opening, solves the maintenance issues of traditional wire mesh strainer.

What's new

We will introduce 2 new products at FILTECH

OKUTANI already has broken the mold and made the impossible possible.

OKUTANI was established in 1895 and has been supplying Wire Mesh and Perforated Metal over 125 years. Our history is a history of challenges, we have always tried and will continue to try new things to meet the demands of our customers.

We are going to introduce 2 new products at FILTECH 2023 in addition to Xtreme High Open Area and Super Punching introduced in 2022.

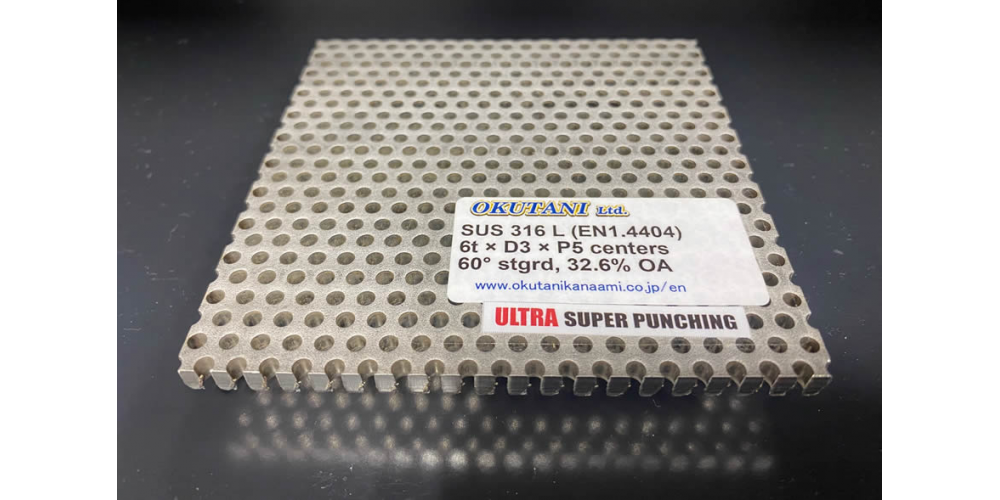

The first product is ULTRA SUPER PUNCHING.

It realizes material thickness twice the hole diameter by punching press. Our new technology allows us to perforate 3 mm holes in 6 mm stainless steel sheet.

6mm’s Tensile Strength increased approx. 2.2~2.7 times and Flexural Strength increased approx. 4.6 times compared with 3mm stainless steel sheet. Also, the production costs of punching press are significantly lower compared to drill and laser.

The second is “Sanitary Strainer using perforated Duplex stainless steel”

By replacing wire mesh with perforated duplex stainless steel, we can achieve,

Longer service life by greatly improving durability and pressure resistance.

High strength, High corrosion resistance, Thermal low-expansion, Polishability and Saving compared with general stainless steel.

Easy foreign substance detection and removal by magnets.

Okutani’s advanced perforating technology enables a wide range of hole diameters from 0.035mm to 1.00mm. Available in two thickness of 0.5mm and 0.8mm.