Haotian Industrial Fabric Co. Ltd. Hall 7 / R26

Exhibitor Profile

Taizhou Haotian Industrial Fabric Co., Ltd founded in 1985, specialized in dust and liquid filtration technology research and development, provide all-round solution design for filtration projects.

The export business started in 2000, established long-term cooperation with customers from more than 30 countires. Haotian owns 5 production lines, the annual production capability for high-temp.

Filter material is up to one million square meters and for normal- temp filter material is five million square meters.

Haotian constantly devotes to the research of new products, and has developed a series of characteristic products with Haotian brand. Haotian provides diversified and personalized products, meets your different requirements for filtration.

Products / Markets

Product Index

- Filterbeutel

- Filtertücher

Market Scope

- Chemische Industrie

- Lebensmittel-,Getränkeindustrie

- Medizintechnik, Health Care Industrie

- Oberflächentechnik

- Umweltschutz

- Zement Industrie (NEW in 2026)

Product Index

- Filter Bags

- Filter Cloth

Market Scope

- Cement Industry (NEW in 2026)

- Chemical Industries

- Environmental Protection

- Food, Beverage Industry

- Medical, Health Care Industry

- Plating Industry

Product Index

- 滤布

- 过滤袋

Market Scope

- 化学工业

- 医疗卫生保健业

- 水泥行业 (NEW in 2026)

- 环境保护

- 电镀工业

- 食品、饮料工业

Product Index

- أقمشة فلاتر

- أكياس فلاتر

Market Scope

- (NEW in 2026)صناعة الأسمنت

- الصناعات الطبية والعناية الصحية

- الصناعات الغذائية وصناعة المشروبات

- الصناعة الكيماوية

- صناعة الألبان

- صناعة الصفيح

Product Index

- Sacs de filtres

- Tissus de filtre

Market Scope

- Industrie chimique

- Industrie des placages

- Industrie du ciment (NEW in 2026)

- Industrie laitière

- Industrie médicale et de la santé

- Industries alimentaires et des boissons

Product Index

- Panno filtrante

- Tasche filtri

Market Scope

- Industria del cemento (NEW in 2026)

- Protezione ambientale

- Settore alimenti e bevande

- Settore chimico

- Settore industria galvanica

- Settore medicale e sanità

Product Index

- Tkanina filtracyjna

- Worki filtracyjne

Market Scope

- Ochrona zdrowia

- Ochrona środowiska

- Przemysł cementowy (NEW in 2026)

- Przemysł chemiczny

- Przemysł platerniczy

- Przemysł spożywczy

Product Index

- Sacos filtrantes

- Tela filtrante

Market Scope

- Indústria alimentar, de bebidas

- Indústria da galvanização

- Indústria do cimento (NEW in 2026)

- Indústria leiteira

- Indústria médica, cuidados de saúde

- Indústrias químicas

Product Index

- Фильтровальные мешки

- Фильтрующая ткань

Market Scope

- Гальванотехническая промышленность

- Медицина, здравоохранение

- Молочная промышленность

- Производство продуктов питания и напитков

- Химическая промышленность

- нтная промышленность (NEW in 2026)

Product Index

- Bolsas de filtro

- Tela de filtro

Market Scope

- Industria cementera (NEW in 2026)

- Industria de la alimentación y las bebidas

- Industria de los productos lácteos

- Industria de los revestimientos electrolíticos

- Industria médica, de la atención sanitaria

- Industrias químicas

Product Index

- Filtre Kumaşı

- Filtre Torbaları

Market Scope

- Gıda, İçecek Endüstrisi

- Kaplama Endüstrisi

- Kimya Endüstrisi

- Tıp, Sağlık Sektörü

- Çevre Koruma

- Çimento endüstrisi (NEW in 2026)

Product Index

- 여과천

- 필터 백

Market Scope

- 도금 산업

- 시멘트 산업 (NEW in 2026)

- 식음료 산업

- 의료, 보건 산업

- 화학 산업

- 환경 보호

Product Index

- フィルターバッグ

- 濾過布

Market Scope

- セメント産業 (NEW in 2026)

- メッキ業界

- 化学工業

- 医療、ヘルスケア業界

- 環境保護

- 食品、飲料業界

What's new

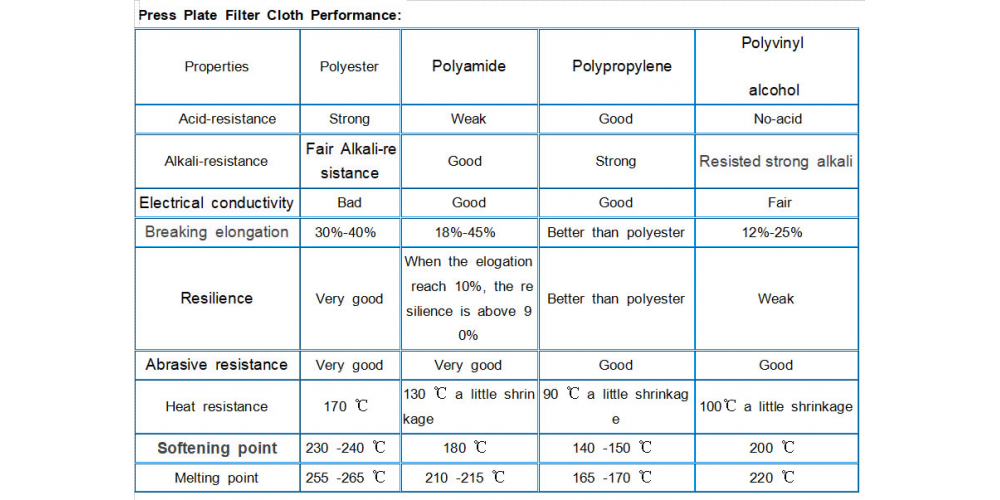

Press Plate Filter Cloth

The filter cloth is a very important component of the filter press, and whether the filter press can work ideally depends largely on the performance of the filter cloth and its ability to achieve solid-liquid separation without blockage or damage. Filter cloth can be divided into two categories based on fiber material. One category is natural fibers such as cotton, wool, silk, and hemp fibers; Another type is chemically synthesized fibers, such as polyester, nylon, polyacrylonitrile, vinylon, acrylic, polyester fibers, etc. According to the yarns that make up the filter cloth, it can be classified into mono-filament yarn, multi-filament yarn, and short fiber yarn. The characteristic of filter cloth woven from single fibers is that it is not easily clogged and has good cake unloading performance. The characteristics of multi-filament filter cloth are high tensile strength, good cake unloading and regeneration performance. The characteristics of short fiber yarn filter cloth are good particle retention performance and the sealing performance it can provide. The filter cloth woven from mono-filament yarn is called "mono-filament fabric"; The filter cloth woven from multi-filament or short fiber yarn is collectively referred to as "multi-filament fabric".

The filtration performance of filter cloth made by different weaving methods varies:

- Filtration rate: plain weave filter cloth<twill weave filter cloth<satin weave filter cloth<non-woven filter cloth;

- Moisture content of filter cake: plain weave filter cloth>twill weave filter cloth>satin weave filter cloth>non-woven filter cloth;

- Filtrate transparency: plain weave filter cloth<twill weave filter cloth<satin weave filter cloth<non-woven filter cloth;

- Unloading performance: non-woven filter cloth<plain filter cloth<twilll filter cloth<satin filter cloth;

- Regenerative performance: satin filter cloth<twill filter cloth<plain filter cloth<non-woven filter cloth;

- Service life: non-woven filter cloth<satin filter cloth<plain filter cloth<twill filter cloth;

What's new

Dust Collect Filter Bags

Hotian can make filter bags according to customer’s demand for reaching optimum filtration performance. Various types of needle felt material can be used for different applications. They are effective in reducing dust emission level according to industries requirement. Hotian insist on helping customer to find the appropriate material for making filter bags. We also provide bags installation instruction and bag replacement service.

Technical Specifications:

All of our filter bags are available in different weights, treatments and coatings to suit the industry application. Standard and specific media materials are:

- Polyester needle felt

- Polypropylene needle felt

- Metamax (Aramide / Nomex )

- Glass fiber needle felt

- Homopolymer Acrylic needle felt

- PTFE

- P84

- PPS

- FNS Series Felt

- Glass/PTFE composite Felt

Available Coating & Treatment:

- Anti-static Treatment With Carbon Fiber

- Anti-static Treatment With Copper Wire

- Anti-static Treatment With Stainless Steel Fiber

- Water & Oil Repellent

- PTFE impregnation

- PTFE Coating

- Media with PTFE lamination

Sizes:

Customized sizes are available in cylindrical tube bags & pocket type bags

Configurations:

- Snap Band Type

- Flange Collar Type

- Rubber Cord Type

What's new

Liquid Filter Bag

Liquid filter bag is a type of industrial filtration product designed to remove contaminants from liquids by passing them through a porous fabric or mesh bag. These bags are widely used in industries such as pharmaceuticals, food and beverage, chemicals, water treatment, and oil & gas to ensure product purity, protect equipment, and meet regulatory standards.

Key Features of Liquid Filter Bags:

Material:

Made from various filter media such as:

- Polypropylene (PP) – Cost-effective, chemical-resistant, for general-purpose filtration.

- Nylon (PA) – Good for high-temperature and high-viscosity liquids.

- Polyester (PE) – Durable and resistant to abrasion.

Applications:

- Removing particulates from water, chemicals, solvents, oils, and beverages.

- Pre-filtration to protect pumps, membranes, and other sensitive equipment.

- Clarification of liquids in food & pharmaceutical production.

Compatibility:

Resistant to acids, alkalis, solvents, and high temperatures (depending on material).

Common Housing Types:

- Single-bag housings (for small-scale filtration).

- Multi-bag housings (for high-flow industrial systems).

Advantages of Liquid Filter Bags:

✔ High dirt-holding capacity – Long service life.

✔ Cost-effective – Lower operational costs compared to cartridges.

✔ Easy to install & replace – Minimal downtime.

✔ Customizable – Various sizes, materials, and micron ratings available.

Industries Using Liquid Filter Bags:

- Water Treatment – Removing sediments and impurities.

- Food & Beverage – Filtering syrups, oils, and dairy products.

- Chemicals & Pharmaceuticals – Purifying solvents and APIs.

- Paints & Coatings – Eliminating particulates for smooth finishes.

- Oil & Fuel – Protecting machinery from contaminants.