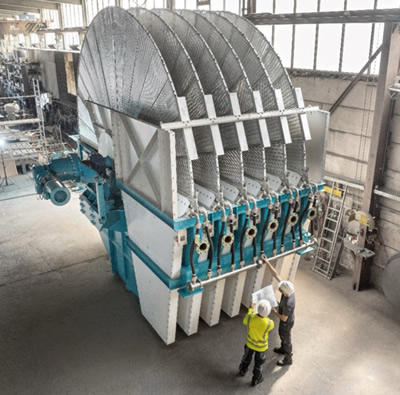

From Idea to Production – New XL352 High-Performance Disc Filter – The Biggest in Tailings

BOKELA GmbH – Hall 8 – A45

The processing of minerals and ores produces tailings as an unavoidable residue. These tailings are either deposited in tailing storage facilities (TSF) or used as backfill in underground operations. In both cases filtration is taking an increasing share. In TSF operations because of increasing sensitivity to safety, environment, real estate, water consumption and last but not least the cost for mine closure. And in backfill cases to minimize the amount of cement/binder which is the major driver of operating cost. Similar to many industries, the capacity per production line of minerals and ore processing is increasing from project to project. The major reason is that the cost for equipment with double capacity is just 50 – 70 % more (not double). Therefore, the total capital expenditure (CAPEX) for bigger projects is decreasing per ton of product and projects become more feasible with a high chance of realization.

Request more information

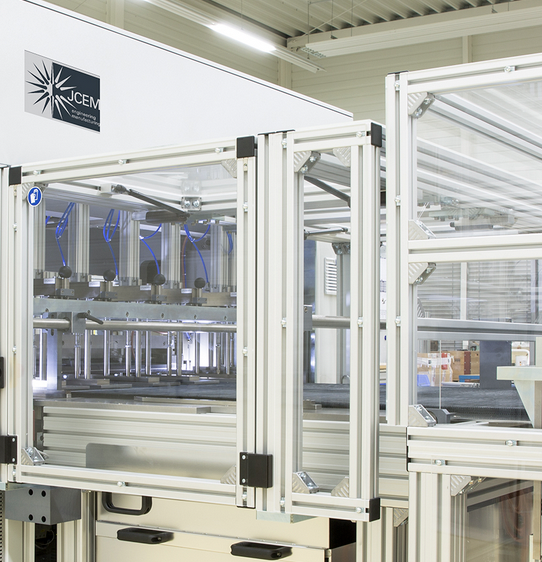

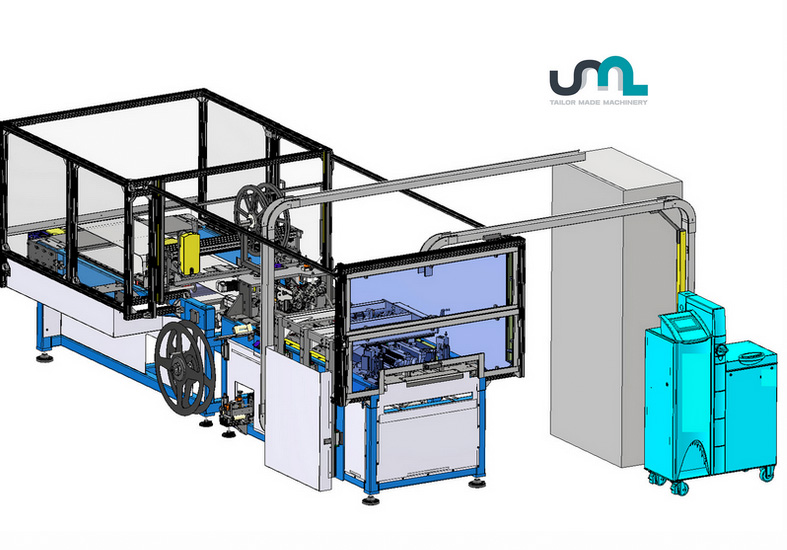

JCEM Group: New TAG Facility & High-Speed Innovations

JCEM GmbH – Hall 8 – E42

The JCEM Group is proud to announce the completion of its new state-of-the-art facility for TAG GmbH, known globally for its high-end Mini-Pleating machinery.

The 3000 sq meter facility on over 6000 sq meter land, just outside Berlin, marks a major milestone, providing the infrastructure needed to support the group’s rapid growth and the continued evolution of its high-tech pleating solutions.

TAG, the industry’s most advanced CNC Mini-pleat system, has redesigned and innovated the Vario Rotafalt, reaching speeds of 600 pleats/min. It features updated drives, PLC, and an HMI with a Production Overview Dashboard for self-diagnostics, an OPC UA Server, and “on-the-fly” and auto-adjustments. TAG’s latest on the fly automatic Cross Cutter further eliminates manual intervention.

JCEM: Setting Industry Benchmarks:

- P7 Heavy Duty Speed Pleater: Optimized for multi-layer wire mesh with maximum throughput and pleat compression.

- Inline Slitter: Now with an optional Automation Feature that fully automates blade and width adjustments without material removal, ensuring the fastest changeovers time, highest precision, lowest waste which brings the pleat pack production to another level of quality and speed, significantly boosting ROI.

- P8 High-Speed Pleater: Achieving 550 pleats/min at common heights between 25-40mm, this Swiss-made machine is built for 24/7 in real production environment.

The JCEM Group, including JCEM GmbH (Switzerland), TAG (Germany), and JCEM Inc. (USA) is the global leader in innovative pleating systems, offering the world’s most innovative, efficient, and robust pleating systems available.

Request more information

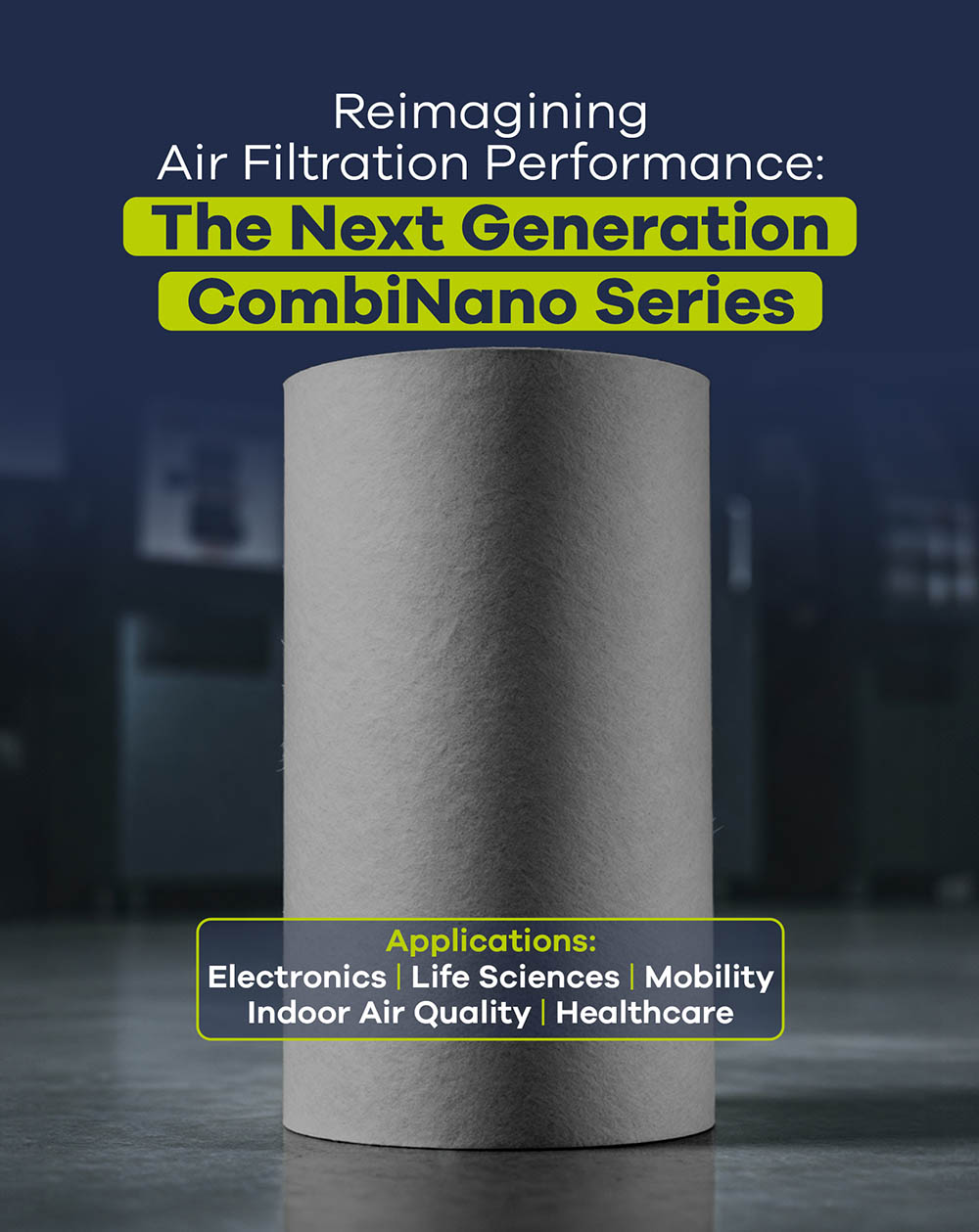

CombiNano: Nanofiber Precision and Activated Carbon Power Combined in a Single Media

HIFYBER – Hall 7 – L5

Air filtration is moving beyond traditional limits.

CombiNano combines gas-phase adsorption and particulate filtration in one advanced media. Unlike conventional solutions that rely on electrostatic charges, CombiNano delivers stable, long-term performance even in humid and chemically aggressive environments. Designed with a 2026 vision, it brings together sustainability and operational reliability.

Why CombiNano?

1. Charge-Independent Nanofiber Filtration

Traditional carbon filters use charged meltblown layers that lose efficiency under humidity and chemical exposure. CombiNano’s nanofiber layer provides purely mechanical filtration, ensuring consistent capture of fine and submicron particles from day one.

2.Microporous Coconut-Shell Activated Carbon

High-purity activated carbon derived from renewable coconut shells offers a dense microporous structure optimized for VOCs and odors, with low ash content for clean operation and stable airflow.

3.Synergistic Protection

Nanofiber captures fine dust before it reaches the carbon layer, preventing pore clogging and preserving gas adsorption capacity throughout service life.

Applications include HVAC systems, data centers, cabin air filtration, and industrial environments.

Contact us for details and samples.

Request more information

Advanced Filtration Solutions Designed for Performance, Durability, and Long-term Value

IREMA-FILTER GmbH – Hall 7 – L7

IREMA, together with parent company Rensa Filtration showcases advanced filtration solutions designed for performance, durability, and long-term value tailored solutions for the most challenging environments.

Learn more about our latest innovations, discuss real-world filtration challenges, and see how our combined expertise supports data centers, OEMs, industrial applications, and more worldwide with a variety of air filter products and air filtration media (particulate and vapor/odor/fume/gas chemical pollutants) manufactured in Germany, Canada and the United States.

Uniquely positioned as a vertically integrated filter manufacturer, IREMA and Rensa leverage proprietary technologies to implement rapid customer developments and the delivery of top-tier solutions with outstanding technical performance – all at a world-class development pace.

- Our extensive machine know-how and in-house mechanical engineering enables us short reaction times during operation and manufacture of our products.

- Manufacturing technology for filter media allows us flexibly to design progressive three-dimensional particulate media, proprietary synthetic HEPA 99.99% media and CarbonWeb® advanced adsorptive activated carbon media.

- When the standard won’t work, we build what does. You bring the specs, the tolerances, the impossible wish list. We build the air filter that integrates into your product and meets its demands, no compromises. In-house custom engineered project management is available from R&D and rapid prototyping to testing and validation services.

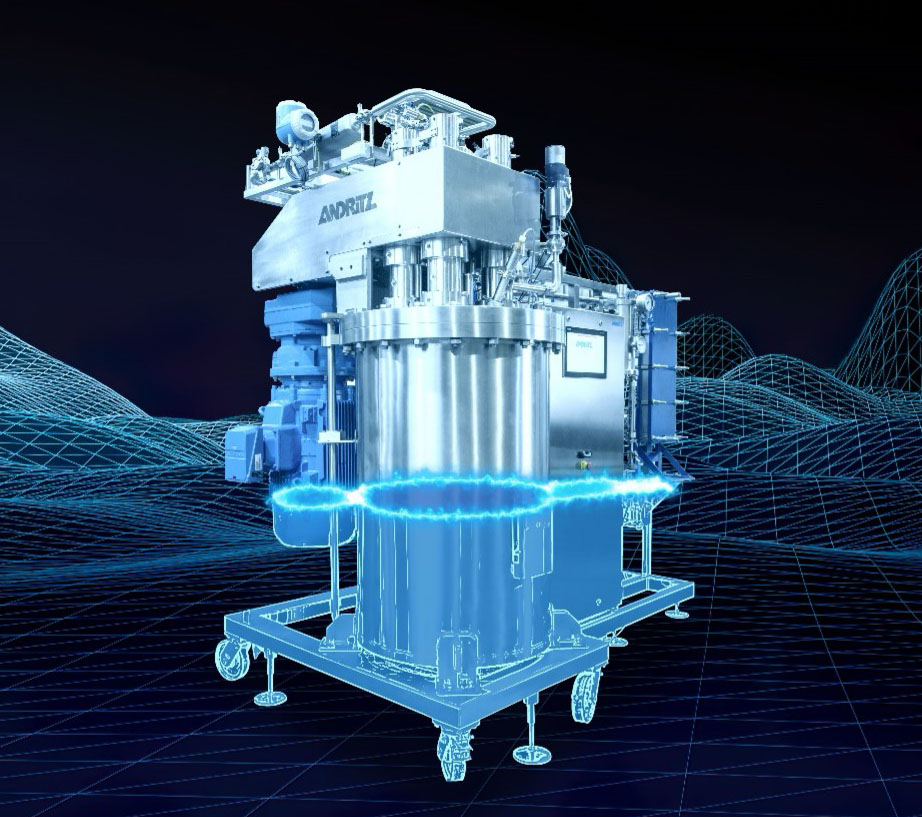

UNDALOOP® SU FILTER - A New Era in Single-Use Filtration

DrM Dr. Mueller AG – Hall 8 – E31

Introducing FUNDALOOP®, DrM’s innovative single-use, multi-cycle filtration system for efficient and scalable solid-liquid separation in Pharma & Biotech applications.

FUNDALOOP® combines the benefits of single-use technology with the performance of multi-cycle operation, previously unexplored in the industry.

What makes FUNDALOOP® different?- Single-Use Filter Bag with Integrated Filter Cloth — multiple vertically aligned filter elements packed inside a pre-contained FUNDALOOP® Bag for high sterility and safe operation.

- Self-Cleaning Back-Flush Cycle — regenerates filter media after each cycle, minimizing cloth fouling and maintaining performance over time.

- High Flow Rates & High Filtrate Clarity — large surface area and smart design for stable, high throughput filtration.

- Multi-Cycle Filtration Capability — allows repeated cycles to handle larger batch volumes with the same system.

- Reduced Waste & Efficient Scale-Up — lower plastic waste, compact footprint and ability to scale without changing core equipment.

FUNDALOOP® is a smart alternative to traditional disposable cartridges, offering higher efficiency, reduced fouling and improved process scalability in cell harvesting, clarification and downstream workflows.

Discover how FUNDALOOP® redefines single-use filtration at Filtech 2026.

Request more information

Evolution of filter testing over more than three decades

TOPAS – Hall 8 – E50

Coming up with two new filter test system categories Topas is setting new standards again.

With the development of ALF 114 filter test system in 2006, we were able to offer our customers a previously unknown test rig for general air filters in accordance with EN 779, ASHRAE 52.2

As both standards have been harmonized to ISO 16890, we did all relevant modifications at ALF 114. Driven by customer requests, from this test system GTS 114 was further developed for gas turbines in 2020 and is now, in its most recent development, equipped with the highly sophisticated integration of climatization through air recirculation.

The new test system offers stable test conditions and provides norm-conform testing according ISO 29461. With it, we are the first commercial supplier of test systems for this special application. At the same time, we are presenting at Filtech 2026 the latest technology development for testing adsorptive HVAC filters according to the new ISO 10121 standard with the GAF 114.

Discover and discuss with us at our booth what we are working on today and in the future: advancing further developments in molecular air filter testing, dealing with new fields of application such as testing of medical filters or the use of our core competencies in fully automated filter testing.

Challenging: Our oversized vision of the future on 7 by 3 meters. Stop by and find out!

Request more information

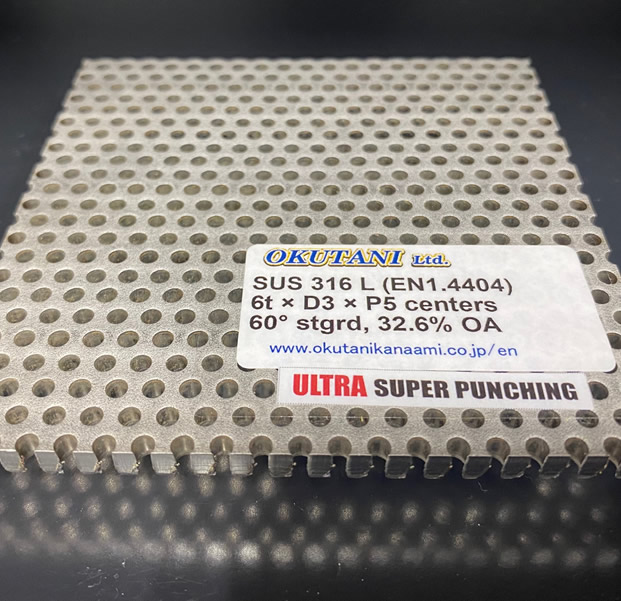

PSC presents: Electron Beam Perforation

Pacific Special Alloy Castings Co., Ltd. – Hall 8 – E38

Pacific Special Alloy Castings Co., Ltd. will present their to ultra high speed and high precision drilling technology at FILTECH 2026:

ー Electron Beam Perforation ー

This is a type of thermal processing in which the surface of the workpiece is irradiated with a highly focused electron beam, locally and for a short time.

Holes are drilled by melting and evaporating caused by the heat generated.

High-density micro holes can be drilled in thick plates with high precision, which is difficult to achieve with conventional processing.

Compared to other drilling methods such as carbide drills, CO2 lasers, and punching, EBP method has the advantage of being able to accurately drill a large number of holes in a short period of time.

Advantages of EBP are:

- Ultra-high speed

- High precision

- Capable of processing into high performance materials (special materials)

- Capable of deep hole processing

- Capable of drilling holes in molded products (complex shapes)

- Oblique hole processing

- Long hole (slot hole) processing is also available

- Hole cross-sectional shape is also selectable

FILMEDIA presents: Intelligent Filter Bags

FILMEDIA – Hall 7 – R35

I. Market Background

Currently, industrial environmental protection requirements are becoming increasingly stringent, and traditional filter bags have pain points such as low efficiency and short service life. With the advancement of the “dual carbon” (carbon peak and carbon neutrality) goals and high-energy-consuming industries require intelligent and highly efficient dust removal solutions. Meanwhile, the maturity of Internet and AI technologies provides technical support for theintelligence of filter bags. As environmental protection standards upgrade andintelligent transformation accelerates, market demand is shifting from single filtration functions to digital operation and maintenance management.

Intelligent filter bags will become an essential choice for dust control across industries, with huge market potential.

II. Industry Status

Currently, dust collectors mainly rely on online infrared thermometers (temperature measuring guns) to monitor temperature:

1. Single-point measurement easily misses local overheating, lacking comprehensive monitoring;

2. In high dust environments, probe contamination can cause data deviations;

3. Electronic monitoring devices may malfunction or fail due to signal interruptions.

III. Intelligent Filter Bags

Traditional filter bags only have basic filtration functions and rely on external devices to monitor operating status, which leads to delayed monitoring, single data sources, and many blind spots. In contrast, intelligent filter bags achieve the following breakthrough advantages by integrating sensors, chips, etc. (Figure 1, Figure 2)

1. Precise real-time monitoring

Directly embedded sensor chips for temperature and differential pressure provide real-time feedback on filter bag status, avoiding measurement errors from external devices.

2. Comprehensive coverage without blind spots

Distributed monitoring points can capture local overheating, blockage, or damage, preventing sudden failures.

3. Proactive warning and maintenance

Data-linked control systems automatically trigger cleaning or alarms, reducing manual intervention and extending filter bag lifespan.

4. Adaptability to harsh environments

No reliance on easily contaminated electronic peripherals; physical detection units (such as temperature-sensitive paper) are more stable under high-temperature and high-humidity conditions.

5. Cost optimization

Reduces downtime and maintenance costs, especially suitable for high-risk industries such as chemical and metallurgy.

Intelligent filter bags will evolve into a closed-loop system of “perception-feedback-optimization,” representing a key innovation for dust removal technology moving toward digitalization and intelligence.

Request more information

Needle vs. Open Surface electrospinning — And Acouspins Game-Changing Third Option

Acouspin – Hall 7 – K21

Electrospinning is transforming industries like healthcare and filtration, but traditional methods face trade-offs. What if there was a way to combine precision, scalability, and reliability in one breakthrough solution?

Needle Electrospinning

Precision: Controlled flow of polymer solution through needles. Scalability: Limited production Applications: Ideal for research and small-scale production requiring specific fiber diameters. Challenges: built in problem of needle clogging and maintenance demands.

Open Surface Electrospinning

Throughput: Utilizes a free liquid surface (e.g., rotating drums or flat plates) to generate multiple jets.

Applications: Large-scale production of filters, membranes, and textiles. Scalability: Higher production rates—great for industrial applications. Challenges: Less precise control over fiber properties and uniformity.

Which Method to Choose?

For precision and control, needle electrospinning is the go-to. For high-volume applications, open surface electrospinning has been the best choice so far.

With Acouspin’s ultrasound electrospinning for nanofibers, you can have the best of both worlds: open surface for high throughput and non-clogging acoustic-needle for precision. Acouspin’s patented ultrasound enhanced electrospinning redefines how nanofibers are manufactured globally.

For more info visit Acouspin at FILTECH 2026 Hall 7 Stand K21 or have a look at their website: https://www.acouspin.com/

Request more information

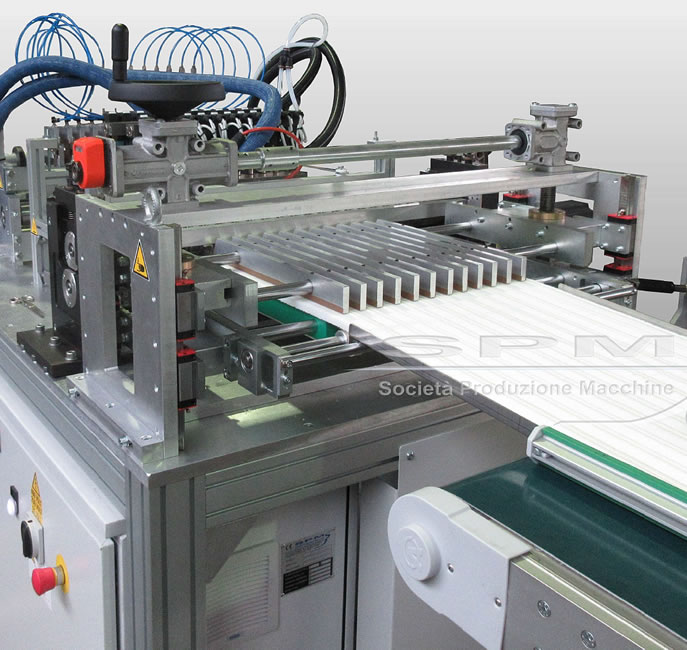

SPM presents: 91XSPL | Servo Blade Pleater & 90XSB | EdgeBanding

SPM Srl. – Hall 8 – E6

The 91XSPL | Servo Blade Pleater is a servo-driven automatic pleating machine for processing single and multi-layer fabrics.

The 90XSB | EdgeBanding is an automatic edgebanding machine for gluing sidebands onto filtering media spaced with dimensioning screws.

Find out more technical details here or at the SPM stand E6: https://spm-macchine.com/en/

Request more information

Brand new from RAMPF: Conductive Casting Compounds with FDA Approval

RAMPF Advanced Polymers GmbH & Co. KG – Hall 8 – E29

Product innovation for the filter industry: RAMPF is introducing its portfolio of FDA-approved conductive casting compounds.

The two-component polyurethane systems are certified under FDA 21CFR175.105 and can also be formulated for compliance with Commission Regulation (EU) No 10/2011.

The casting compounds stand out with their exceptional conductivity of less than 1 MOhm/cm, while still maintaining a low mixed viscosity between 3,500 and 5,500 mPas. This makes them highly flowable and self-leveling.

For users, this means that complex processes are no longer necessary, significantly simplifying and streamlining casting applications.

The casting compounds also provide excellent chemical resistance and are available in a range of Shore hardnesses from Shore 50A to Shore 80D.

Contact us for more information: advanced.polymers_at_rampf-group.com

Request more information

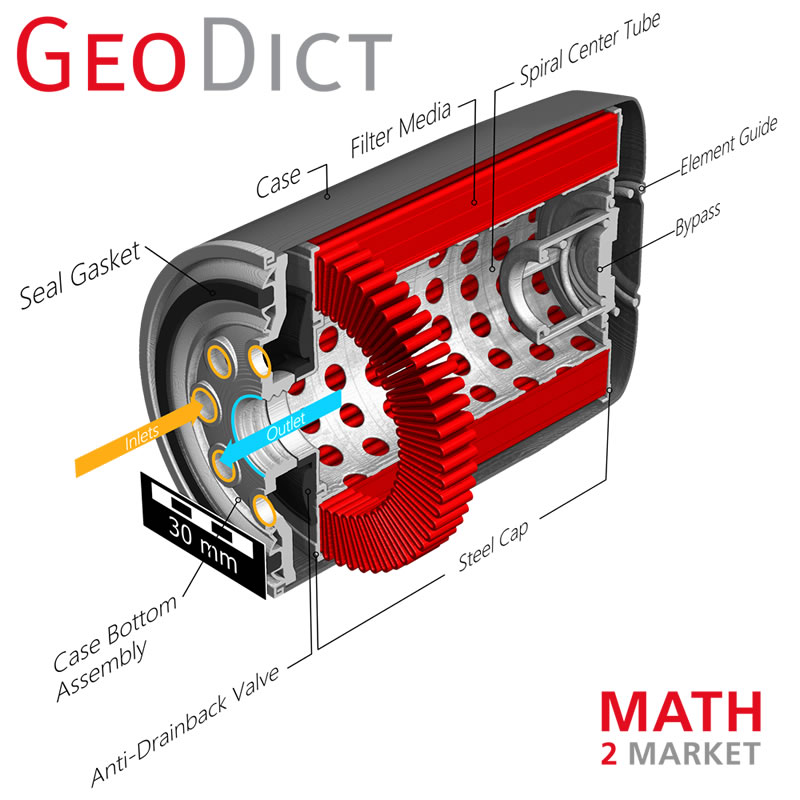

GeoDict software for advanced simulation of next-generation electret filters

Math2Market GmbH – Hall 8 – B26

Electret filters are known for their superior filtration efficiency, but research on their improvement faces numerous challenges and complexities: charge stability over time, charge uniformity and distribution of charges.

As a valuable alternative, our cutting-edge FilterDict module of the GeoDict software provides valuable insights into the complex interplay among electrostatic forces, airflow dynamics, and particle behavior, aspects not easily observable or measurable through experiments.

FilterDict capabilities have been enhanced* to perform advanced numerical simulations of electrophoresis and dielectrophoresis, simulations of diverse charge distribution in both particles and fibers, and tracking of surface charge decay in electret filter media over time.

These simulations bring now already the possibility to engineer innovative next-generation electret filter media with different charge distribution methods, structural configurations, and improved charge stability. Unlock the next era of filtration design today!

Request more information

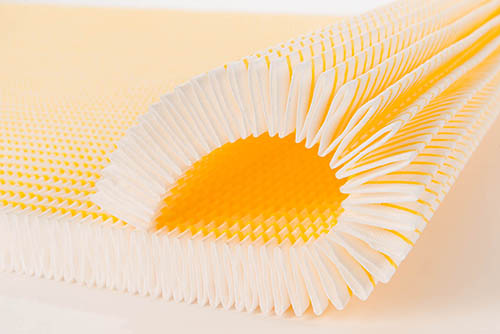

New high-performance materials for engine air intake filters

AHLSTROM – Hall 7 – P2

We have introduced a new dual-layer filter media technology, which represents a leap forward in filtration and is a perfect solution to comply with future market needs. The dual-layer design offers up to double dust holding capacity compared to the single-layer design, as each layer serves a distinct purpose to optimize the overall retention of particles in the depth of the material.

In automotive engine air intake applications, the technology has proven to extend by over 50% the filter lifetime in the same configuration. It also offers the possibility to reduce both size and weight of the filter element in vehicles where these parameters are important.

Dual-layer filter materials are designed to comply with current and future engine air intake specifications, including fuel cells. The media can be customized with flame retardancy properties to increase safety in use without compromising performance.

The technology is highly adaptable and can be extended to filter air and liquid in many other transportation and industrial applications. Let’s discuss further at FILTECH, please stop by our booth P2 in hall 7.

#purifyandprotect #innovation

#filtermaterials #filtermedia

JCEM proceeds with the advanced ongoing innovation

JCEM GmbH – Hall 8 – E56

JCEM releases its latest P7 Heavy Duty Speed Pleater, for multi-layer wire mesh pleating, with highest material throughput and high pleat compression. We also introduce our fully automatic Inline Slitter blade change to change slit widths without any operator involvement, and without removal of material. It offers customers the fastest change over time, highest precision, lowest waste and brings the pleat pack production to another level of quality and speed. The result is an extreme improvement for the customers ROI.

Our P8 High-Speed pleater offers the highest speeds even at common industry pleat heights, between 25-40mm, being pleated with approximately 30m/min (500 pleats/min). Our Swiss made machinery not only achieves record speeds but also provides high reliability and is designed to run 24h/7days in real production environment.

TAG, the most advanced CNC Mini-pleat system, redesigned and innovated the latest Vario Rotafalt with all new Drives, PLC, and brand-new HMI including Production Overview Dashboard (for machine self-diagnostics/preventive maintenance), OPC UA Server, resulting in more on the fly options and auto adjust features. Also available is TAG’s latest on the fly automatic Cross Cutter which eliminates operator involvement in the cross-cutting process.

JCEM Group, including JCEM GmbH (Switzer land), TAG (Germany) and JCEM Inc. (USA), is the global leader for all types of pleating equipment, offering the world’s most innovative, efficient, and robust pleating systems available.

Request more information

Molecular filtration performance at the highest level

TALAMON GmbH – Hall 8 – E38

Wherever conventional filter technology reaches its limits, Talamon’s filtration solutions are in their element.

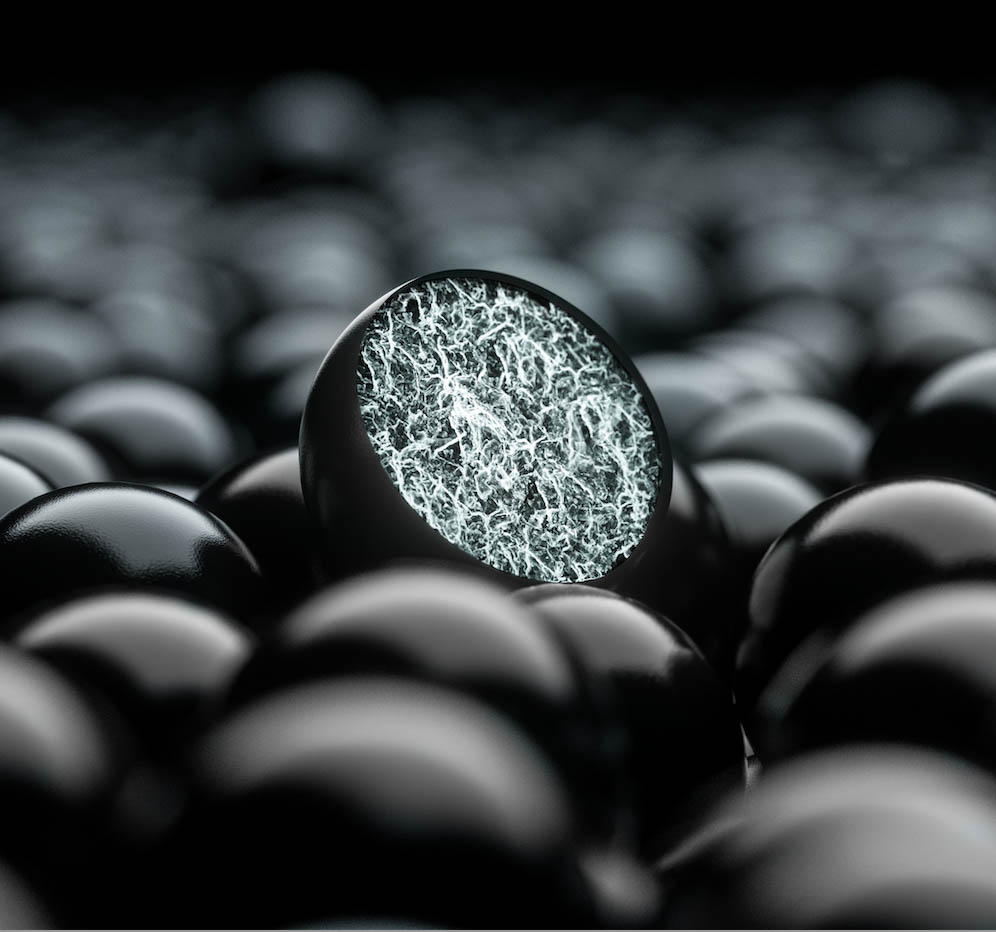

The product range of the Premium line is characterized by foam and pleatable flat filter media based on spherical high-performance adsorbents of polymer origin and ion exchangers for very special applications and requirement profiles.

These products are well known in air filter applications such as aerospace, medical technology, clean rooms, special automotive solutions, kitchen ambient air and others.

Now Talamon is expanding its product range to include filter media based on granulated activated carbons to reach new markets.

The new Standard line also includes product solutions with impregnated carbons, from acidic and basic functionalisation to broadband impregnations for a wide spectrum of pollutants in the treatment of air and gas flows.

The products from both lines will be presented at Filtech 2024. The Talamon team looks forward to welcoming you to booth E38 in Hall 8.

Request more information

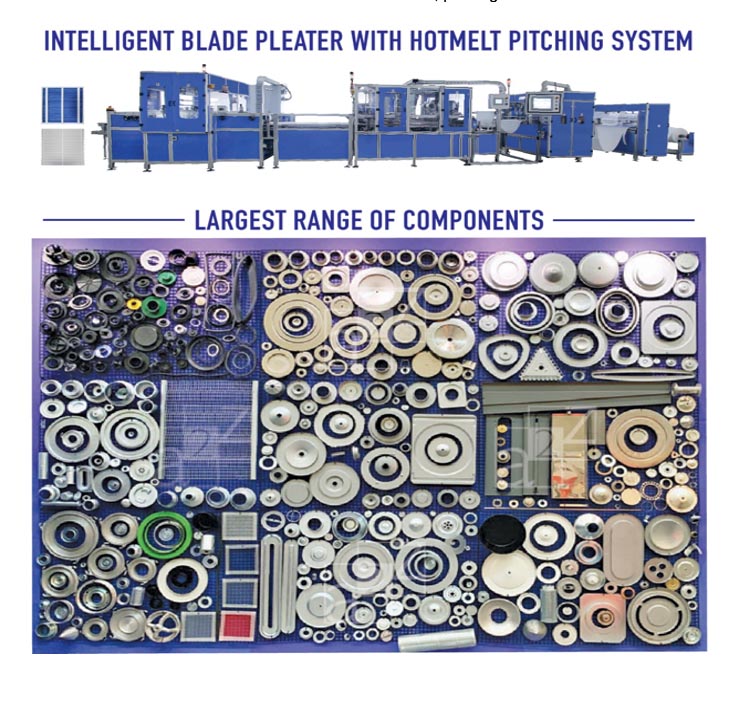

a2z will showcase their Intelligent Blade Pleater and Next Generation Servo Blade Pleater at FILTECH 2024

a2z Filtration Specialities Pvt Ltd. – Hall 8 – A9

A2Z will be showcasing its Intelligent Blade Pleater with a multi axis Pitching System. The line consists of A2Z Next Generation Servo Blade Pleater, pitching line and cross cutter.

Their deep knowledge of filter manufacturing processes and their ability to develop customer specific, innovative and efficient automation has resulted in development of fit-to-purpose solutions.

Largest Range of Components

A2Z Filtration Specialties manufactures a large variety of end caps, components and parts to suit the assembly of all types of filters. A2Z supplies products in injection molding, sheet metal duly stamped, machined and cast. With a range of over 6500+part numbers.

The latest version of SolidWorks ® is used to design all tooling. All tooling’s are manufactured inhouse on HAAS CNC machines for quick turnaround & extremely short lead times.

Product Range includes:

- End Caps,

- Expanded metal,

- Injection molded parts,

- CNC Machined Parts,

- Gaskets,

- Weld Mesh Cages,

- Deep drawn housings,

- Threaded Top cover plates,

- Perforated Sheets,

- Perforated Tubes,

- Springs,

- Panel Sets,

- Frames

- and By-Pass Assemblies.

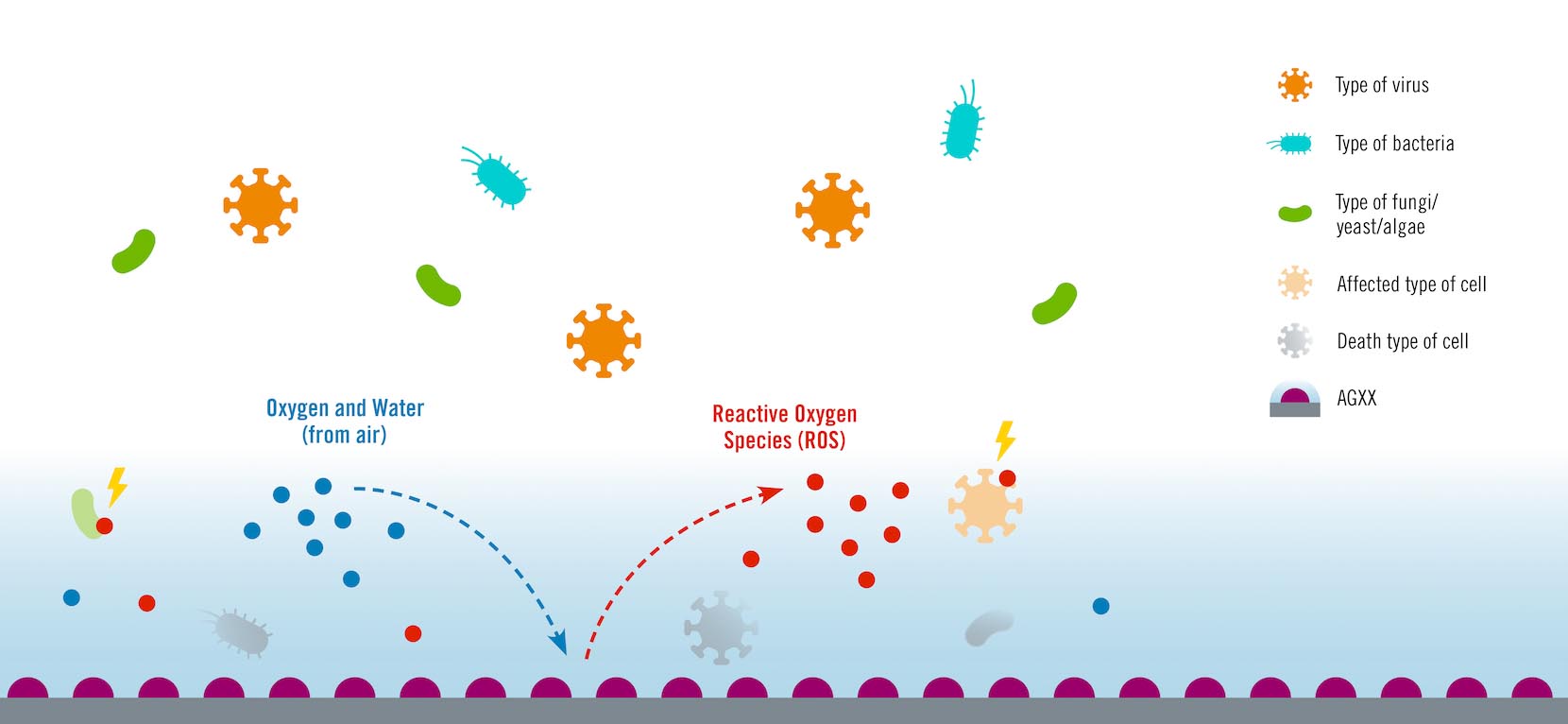

Effective and regulatory-compliant antimicrobial protection of filter media with AGXX technology

Heraeus Precious Metals – Hall 7 – M11

Heraeus Precious Metals is proud to present their AGXX technology – an environmentally friendly solution for antimicrobial technologies

Water filters are susceptible to contamination by microorganisms and biofouling, posing a risk to both consumer health and the lifespan of the products. As regulations become stricter towards the release of potential hazardous compounds, particularly in Europe, it is increasingly challenging to effectively protect filter media from microbial contamination in a regulatory-compliant manner, as the currently prevailing technologies based on the release of silver-ions are in the process of being banned by the regulatory authorities (ECHA).

Conventional antimicrobial technologies, including silver-ion-based methods, rely on the release of toxic substances. In contrast, the AGXX technology operates by catalytically generated reactive oxygen species (ROS) from ambient air and humidity. AGXX meets current regulatory requirements and provides an environmentally friendly solution.

Additionally, efficacy tests in accordance with ASTM E 2149 conducted at QualityLabs BT GmbH have demonstrated that activated carbon functionalized with AGXX achieves a higher antimicrobial activity than activated carbon functionalized with a conventional silver technology. This highlights the potential of AGXX as a superior alternative in water filter applications.

Request more information

Adsorption simulations for pollution control and carbon capture – GeoDict software

Math2Market GmbH – Hall 8 – B26

Adsorption-based processes, essential to reduce environmental pollution and eliminate harmful substances, commonly use filter media materials: activated carbon, zeolites, and metal-organic frameworks, to effectively purify fluids and gases in water treatment or air purification.

Breakthrough curves are assessed to measure and classify the quality of adsorption filter media. The curve shows the adsorbate concentration in the filtrate behind the filter media and the breakthrough that occurs when adsorbate appears in the filtrate. However, determining breakthrough curves for a specific contaminant often requires time-consuming and costly experimental procedures.

The new feature in the GeoDict simulation software of Math2Market makes possible to calculate the molecular movement of particles and to solve for the adsorption equilibrium step-by-step using Langmuir and Toth adsorption isotherms.

These most advanced simulations deliver breakthrough curves for various contaminants. Adsorption is vital in carbon capture to trap and store CO2 emissions from industrial activities and power generation, and prevent their release into the atmosphere, making these simulations a great step towards sustainable engineering.

Request more information

vombaur Presents: Specialized Seamless Filtration Textiles for the Chemical Industry

vombaur GmbH & Co K – Hall 7 – P23

vombaur is developing and manufacturing high performing Filtration Textiles as a development partner, i. a. for the chemical industry.

High temperatures, mechanical load, acid resistance – the requirements here are numerous and particularly high. Our seamless, round woven filter tubes made from high-tech yarns meet them: The material, fabric type, weaving technique and finishing is based, e. g. on the burst pressure, pH value, chemical resistance or operating temperature.

With vombaur filtration textiles, there are no seam or weld contours that could impair the filtration process. Flow behaviour, load capacity, shrinkage behaviour, material thickness – our seamless filter textiles possess these central filtration properties over the entire surface of the tubular. Our tapes and belts perform indispensable tasks in the assembly of filter textiles.

Seamless filter sleeves, uniform filtration properties

• Seamless woven tubulars

• High performance yarns

• Uniform filtration

• Maximum process safety

• Precisely specified

• Tailor-made

Materials: PES, PA, PP, PPS, PVDF, PTFE, PEEK, metallic, and further high performance yarns

Fineness: monofilament 35 μm to 500 μm, multifilament 48 dtex to 3300 dtex

Flat width: standard up to 350 mm, custom-made products: up to 950 mm

Boost Air Quality and Productivity with IN-EX HVAC Filters

A.L. Group – Hall 7 – L08

Now that the EPBD (Energy Performance of Buildings Directive) mandates standards for healthy indoor air quality, A.L. GROUP provides the simplest way to enhance EPBD scores with IN-EX HVAC filters.

Utilizing cutting-edge Sono-Chemical technology, these filters are impregnated with metal oxide, enabling the most efficient capture and neutralization of harmful bacteria and viruses with over 99.9% proven efficacy against Influenza (H1N1) and over 99.99% efficacy against E. coli and S. aureus.

IN-EX filters are the ideal solution for any indoor setting, including commercial and industrial environments, with an emphasis on food and medical production where air quality is crucial.

This plug-and-play solution provides a straightforward, cost-effective upgrade to existing HVAC systems, without the need for new infrastructure or complex maintenance.

EPA and BPR-approved IN-EX filters not only enhance public health and building maintenance but also create a safer, more inviting environment for all.

Request more information

LENZING OptiFil improved design innovation

LENZING Filtration – Hall 7 – L12

A reliable solid-liquid filtration that …starts where others stop

A strategic redesign program of the LENZING OptiFil has been developed with the target to maintain competitive pricing and to possibly even extend the application fields to slightly less demanding ones (never to low end markets).

One positive factor enabling a more cost-efficient design has been the increasing numbers sold over the past years and therefore the lot sizes produced.

This allowed for a couple of price-positive design changes such as the increased use of investment casts and a higher degree of standardization using common parts for different sizes and different models.

The additional changes include:

- Standard design pressure of vessel: now: 16 bar/200°C (previously: 10 bar/100°C)

- Pressure vessel codes: more modern EN13445 instead of AD-Merkblätter

- ASME-Coded design with no price adder

- Lower number of parts (and spare parts) simplifies system.

- Shorter lead times for standard filters

The new model OptiFil-S (“S” for Standard) launched this year could manage to keep pricing stable even under rising labor costs while keeping all the standard features allowing for highest backwash efficiency and versatile use. Material of construction from carbon steel to super duplex, shaft seal versions form lip seal to double acting mechanical seal and others.

The new model OptiFil-L (“L” for lean version) accommodates internals that are fabricated at lower cost, with slightly less accuracy, keeping still the main feature of a seal between feed chamber and reject chamber – but omits the feature of an exact positioning after each backwash. Thus, it forms a lower cost version that is targeting for applications slightly less demanding. Since the housing is the same, it is still possible to upgrade to OptiFil-S, should an application proof to be more demanding than previously anticipated.

Request more information

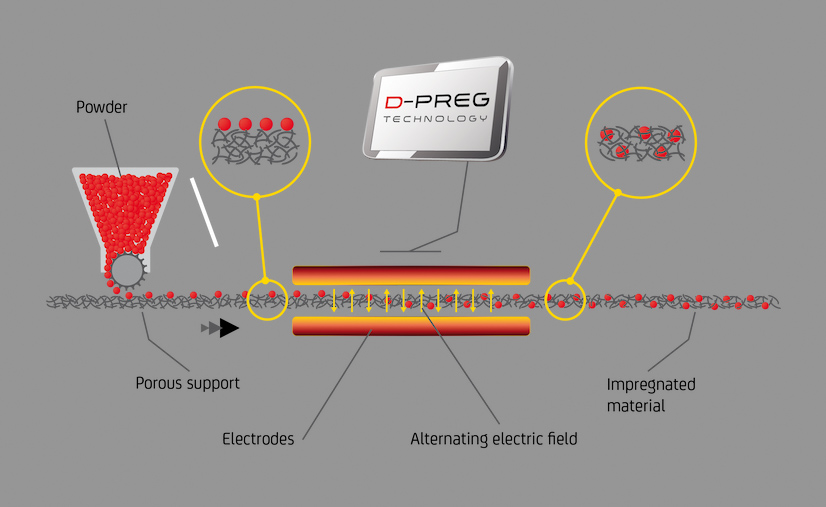

FIBROLINE presents at FILTECH: D-PREG Technology

Fibroline SA – Hall 8 – F38

Fibroline SA has developed and patented dry impregnation technologies. These solutions enable the impregnation of various powders into porous structures homogenously thanks to high intensity alternating electric fields. One main advantage of these innovative technologies is no need for water or solvents.

Dry impregnation can be used for both thin or relatively thick filter media. Many different powders can be impregnated to achieve the desired functions. Recently, Fibroline have made important improvements to capture/extract specific molecules from air or liquids thanks to active powders, for example: MOFs (Metal Organic Frameworks), zeolites and ion exchange resins. By using porous particles with controlled geometries, the targeted molecules are trapped in a very selective way.

The Fibroline technologies give a homogeneous distribution of the particles throughout the porous media. The use of smaller particles will also increase the active area and give higher adsorption capacity and faster adsorption/desorption kinetics.

Promising results have recently been obtained for water treatment (arsenic removal, ion extraction, etc.) as well as for air filtration (capture of hazardous gasses in CBRN applications, CO2 capture or odor removal).

Request more information

FILMEDIA presents their Spunlace Felts - the next promising product in dust filtration!

FILMEDIA – Hall 7 – R35

At present, most customers chose needle felt as the filtering material for Dust Collectors. But compared with Needle Felt, Spunlace Felt has following advantages:

- With smaller pinholes and more even pore

- Higher filtration efficiency

- Lower dust emission standard : ≤10mg/NM³

- Reduce working pressure drop by half

- Reduce energy consumption

- Increase the service life of filter bags

Filmedia adopts advanced German made MONFORTS finish line, FLEISSNER spunlace line and drying machine to make sure lower shrinkage, better mechanical performance. And this will greatly lower down factory’s running cost.

The principle of Spunlace Felt is to use high-pressure water jets to continuously spray the fiber web, so that the fibers move and displace under the action of water force, and rearrange and entangle with each other, thus forming a filter material with very high strength.

Request more information

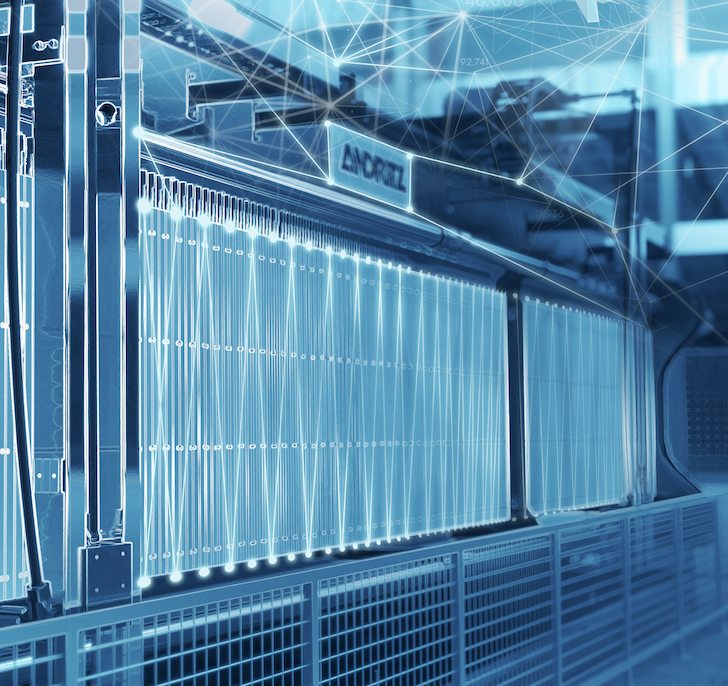

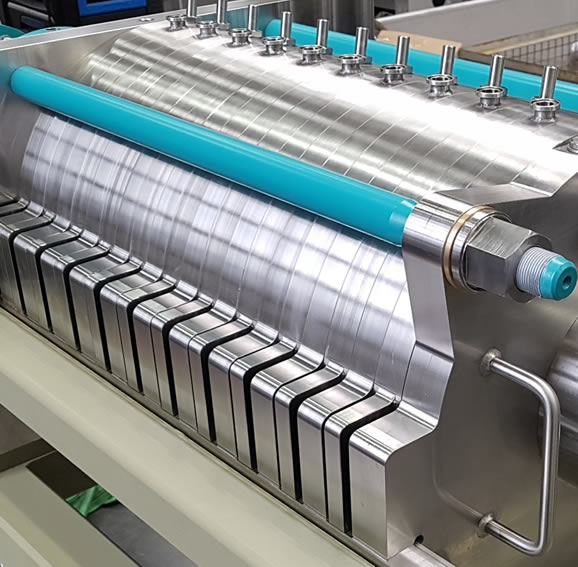

Intelligent cloth washing with ANDRITZ SEPARATION

ANDRITZ SEPARATION GmbH – Hall 8 – F42

Based on sensors’ measurements it is possible to determine the right moment to start the filter cloth washing.

Shifting plate online monitoring: If the system detects deviations from nominal values, the filter press is stopped automatically. This action ensures operating safety.

Online monitoring of the plate package: If the measurements taken deviate from nominal values, the system provides a recommendation to the operator to conduct an automatic washing cycle. In addition, the intelligent filter press detects any deviations from nominal pressure at the beginning of the filtration process:

- Monitoring of filter cloth performance

- Keep capacity/throughput at highest level

- Cloth washing on real demand

Undeniable advantages are provided by both features. The intelligent cloth washing enables up to 20% longer lifetime of your filter cloth and a filter press, that operates under optimum mechanical conditions. This reduces the OPEX of your machine and guarantees maximum safety for the operators, as the sealing areas are clean.

Request more information

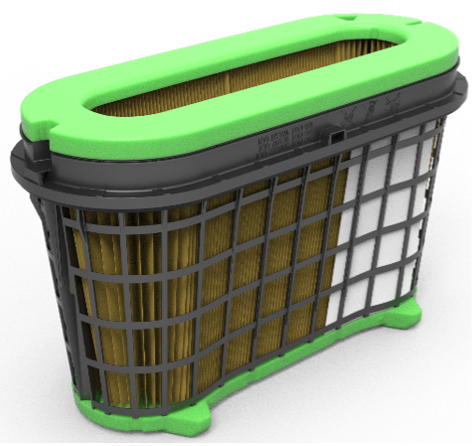

Cathode Air Filter Element for Fuel Cell Applications

MANN+HUMMEL GmbH – Hall 8 – C11

The innovative Flat Cathode Air Filter Element designed to ensure optimum air quality and performance for fuel cell systems. It efficiently removes harmful gases from the cathode air path and protects your system from contaminants. The filter element has four stages. The first and second stages are comprised of a synthetic fleece for pre separation and a cellulose particle filter element for high dust holding capacity. The third stage is an adsorption filter that efficiently eliminates harmful gases such as sulfur dioxide (SO2), nitrogen oxides (NOx), and ammonia (NH3). The fourth stage which is a synthetic layer on the clean side ensures high CCM requirements.

Experience the future of air filtration with our Cathode Air Filter Element. Visit our booth to learn more about how this technology!

Request more information

Next-level crossflow filtration with adaptive control: The Metris addIQ digital twin for Dynamic Crossflow Filters (DCF)

ANDRITZ SEPARATION GmbH – Hall 8 – F42

For most players in the food and chemical industries, using a Dynamic Crossflow Filter (DCF) is an efficient means of filtrating different products. Today, however, operations need to be significantly improved to increase productivity, reduce OPEX, and improve product quality – something which is now possible thanks to the Metris addIQ digital twin. This solution combines advanced automation and digitalization solutions to optimize efficiency and maximize profits.

The Metris Digital Twin represents a digital replica of the physical process using asset-specific information such as actual physical dimensions and equipment characteristics. When connected to online plant data, the Metris Digital Twin acts like a performance information tool similar to an MRI of the human body – both can be used to find otherwise undetectable anomalies and highlight the gaps between actual and optimal operation. The system runs in parallel with your operations, continuously calculating key process parameters that sometimes cannot be measured or are difficult to measure with traditional instrumentation. Thanks to its proven simulation capabilities and combined with live plant data, the Metris Digital Twin provides virtual plant transmitters, it calculates optimal setpoints, and performs what-if scenarios analysis. The data reconciliation helps with online model correction and replaces faulty measurements with plausible values.

Request more information

The new compact filters for molecular contamination according to ISO 10121-3

MANN+HUMMEL Molecular GmbH – Hall 8 – C11

The newly developed Carboactiv Cube Carb and Carboactiv Cube Duosorb compact filters from MANN+HUMMEL offer maximum energy efficiency. The molecular filters provide comparable pressure drops to particulate filters and can be replaced using existing filter configurations.

Now certified according to ISO 10121-3:

ISO 10121-3 is the first classification system for molecular filters for general ventilation applications and helps with the selection of molecular filters for specific supply air applications through easily understandable filter classes.

Application areas

With their outstanding filtration performance, the compact filters ensure clean air in HVAC systems and solve a variety of problems with molecular contamination. They can be used universally, e.g. in commercial kitchens, airports or museums, and improve indoor air quality. Replacement is possible without increasing the energy consumption of the ventilation system.

For more details, visit us at our stand C11!

Request more information

Sustainable Filter Elements by MANN+HUMMEL

MANN+HUMMEL GmbH – Hall 8 – C11

The latest innovation in filtration technology focuses on sustainability without compromising performance. By utilizing renewable materials, we have significantly reduced the product carbon footprint of a heavy duty air filter element. The new design incorporates recycled plastics and bio-based raw materials. This innovative approach not only conserves resources but also positively impacts the CO2 footprint, while fulfilling automotive customer requirements and test standards.

Join us in embracing a greener future with our sustainable filter elements, designed to meet the stringent specifications of the automotive industry while promoting environmental responsibility.

Request more information

Herding® OMIKRON - Adaptable Cleanable Sterilizable

Herding GmbH Filtertechnik – Hall 8 – C29

The new Herding® OMIKRON element is a washable and sterilizable unibody filter element made of polyethylene. It is food compliant according to FDA and European guidelines as well as PFAS-free. This makes it future-proof and in line with upcoming regulations and legislation.

A special feature is that the geometry and connection of the sintered rigid filters is freely adaptable. Thanks to this parametric design, Herding® OMIKRON can be tailored precisely to any application and can therefore also be integrated into existing systems.

This allows maximum flexibility and pure productivity!

Strict hygiene requirements in the food and pharmaceutical industries often make it necessary to regularly replace disposable filters made of paper or textiles to prevent the formation of bacteria. Herding® OMIKRON can be washed or sterilized after product contact or when changing products to make it germ-free again. Therefore it can be used repeatedly while greatly reducing operating and disposal costs.

The fiber-free sintered unibody allows contamination-free product recovery, for example in the case of pneumaticconveying or in industrial vacuum cleaning systems.

Request more information

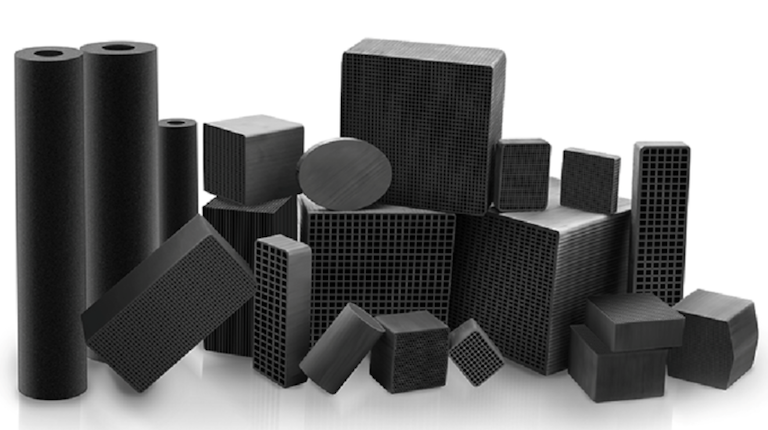

Hanyan presents: cutting-edge honeycomb activated carbon and carbon filter technologies

Hanyan Activated Carbon Technology Co., Ltd. – Hall 7 – K29

Discover the future of air purification with HANYAN—your trusted global leader in cutting-edge honeycomb activated carbon and carbon filter technologies. Our new honeycomb activated carbon with over 100% H2S breakthrough capacity will make its debut at the upcoming Filtech, perfect for a broad range of industrial and commercial applications.

Don’t miss out on our star attraction at Filtech: the GridFilter, our best-selling gas-phase air filtration medium. Engineered for robust VOCs & Odor Treatment, Acid Gas Treatment, and Alkaline Gas Treatment, GridFilter excels in the most demanding environments:

- Optimal for high airflow settings (>500 fpm) .

- Resilient in temperatures up to 300℃.

- Effective in up to 99% RH humidity levels.

- Versatile mounting options—horizontal or vertical with bi-directional airflow.

- Designed for maximum removal of gaseous contaminants and enhanced protective performance.

As pioneers in activated carbon production, HANYAN doesn’t just lead the market—we drive innovation through customized solutions tailored to your specific filtration needs. Join us in setting new standards in air quality management.

Request more information

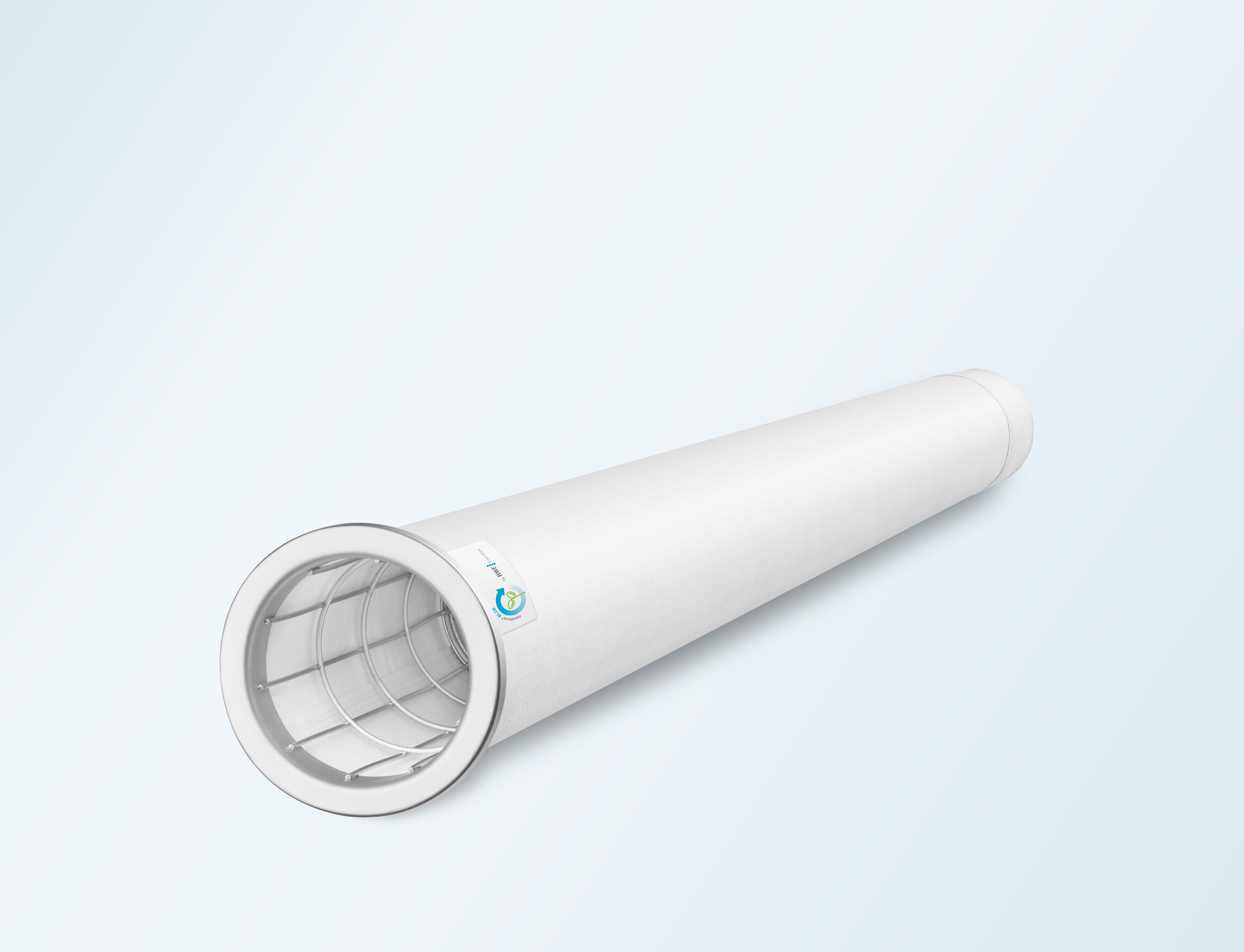

Reducing energy costs in air filtration with the patented Kappa Waveline® bag filter

Kappa Filter Systems GmbH – Hall 8 – L17

Bag filter systems play a crucial role in various industries by providing an efficient and reliable method of separating contaminants from production processes. These systems are essential for maintaining clean air in environments where dust and otherparticulate matter are generated. In bag filter systems, exhaust air from various processes is fed through flexible bag filter elements, which effectively separate and capture dust emissions, ensuring a cleaner and safer workspace.

The patented Kappa Waveline bag filter can be used to optimize existing or newly planned bag filter systems. The Kappa Waveline® bag filter has 25% more filter surface area, supported on the patented Waveline® support basket with the installation size of a standard bag filter. The increased filter surface area leads to a lower filter surface load at the same volume flow and thus to a reduced pressure loss. The result is significantly reduced energy consumption, in some cases by 30-60%, and thus lower operating costs for the filtration of emissions.

The 25% increase in filter surface area also supports the cleaning effect and reduces the number of cleaning sequences required. This improved cleaning leads to significant savings in compressed air.

Request more information

HiBar Drum Filters – The answer to new filtration challenges in battery, minerals and rare earth processing

BOKELA GmbH – Hall 8 – A45

The world is moving into a new era where machinery drives do no longer run with combustion motors, but more and more with electrical motors – getting the power preferably from a green grid.

The metals and minerals required for electric motors are mainly copper for the winding, aluminium for the casing and iron-cobalt-nickel, neodym-iron-bor or samarium-cobalt for the permanent magnets. The metals required for the batteries are mainly lithium, nickel, manganese, cobalt (NMC with high energy density) or lithium, iron, phosphate (LFP with lower energy density).

Especially elements like lithium, cobalt, neodym, samarium or other elements of the rare earth fraction appear in very low concentration in minerals and require an intense hydro metallurgical processing.

This processing requires several steps of solids liquid separation steps with challenges such as extreme pH-values (<2 or >12), temperatures > 100 °C, intense wash of solids, low moisture, continuous operation, etc. Especially intense wash of solids quite often ends up in two or three steps of filtration with intermediate solids reslurry. However, this pushes CAPEX for filtration equipment to the high end and puts the realization of projects at risk.

Modern pressure drum filters such as the BOKELA BoHiBar Drum XL 18 or XL 26 are able to perform a three-stage counter current cake wash with a slurry that is fed to the filter with a temperature of up to 200 °C and solids with a d50 of down to almost 1 micron.

The design of the filter with:

- A high number of individual filter segments

- A quick drainage of the liquid into the piping system to the control head

- A sharp separation of the wash liquids in the control head

- An operation with back pressure on the filtrate separators

…result in reaching the target figures with only one filter unit while other filter types like plate and frame filter presses require two filters with intermediate reslurry. Or the material of construction does not allow for temperatures in the range of 100-200 °C. Furthermore, this filter can be equipped with a steam hood to reduce the moisture to a minimum.

Request more information

JP Air Tech Introduces Advanced Multi-Layer Filter Media

JP AIR TECH – Hall 8 – E35

Discover Innovation with JP Air Tech’s latest advancements in filter media for static filtration. Our new investment in ultrasonic bonding technology has led to exceptional multi-layer filter media targeting HVAC, cabin air, APC, gas turbine air intake, and other applications requiring high dust holding capacity and low pressure drop.

Our multi-layer filter media, certified and classified according to ISO 16890 standards, ensures efficiency and performance across various filtration classes and basis weights. These innovations set new standards in the filtration industry, enhancing air quality and operational efficiency.

Don’t miss JP Air Tech’s revolutionary products. Visit us at Hall 8, Stand E35 to see how our advanced filter media can transform your filtration systems.

Request more information

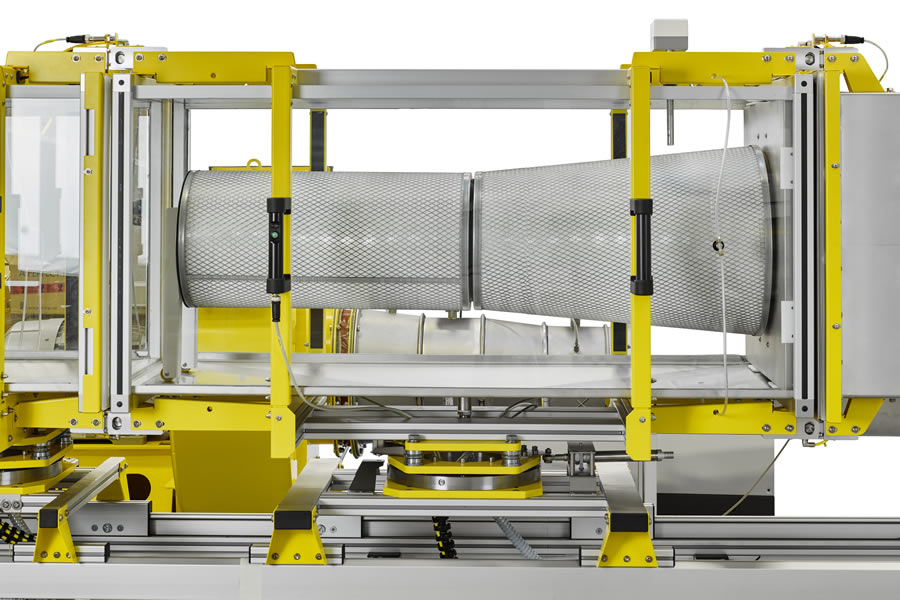

BoVac Disc XL352 – The largest and best-performing vacuum disc filter on the market

BOKELA GmbH – Hall 8 – A45

Modern high-performance disc filters such as the BoVac Disc Filter have set new standards in applications where large capacities of solids, liquids and air have to be managed through the filters.

These disc filters have an enormous hydraulic capacity. For applications in mineral processing – with a special focus on tailings – which typically have high solids throughputs but low filtrate and air flows, this capacity can be used to expand the filtration area while maintaining the benefits of very good cake discharge even with thin cakes (4-5 mm) and a high filter speed.

Research work over the last century has proven that increasing the filter area should be achieved by increasing the disc diameter. Because adding more discs leads to big problems with the cake discharge. However, as the disc diameter increases, the filter segments become longer and heavier.

The BoVac Disc XL352 is the perfect essence. With a filtration area of 352 m² it is the biggest vacuum disc filter on the market. The disc diameter is 6.4 m and the filter has six discs. In tailing applications, the capacity can exceed 1.000 t/h per filter at a moisture of 16-18 %-m/m or get a moisture of 13-16 %-m/m at a reduced capacity.

However, this filter is as well very suitable for coal, ore concentrates and hydrometallurgical separation steps. Particularly in tailings dry stacking projects this filter offers a significant reduction in OPEX and CAPEX compared to the use of pressure filtration with filter presses.

Request more information

Water Systems International presents: NSF certification for POE systems

Water Systems International – Hall 8 – F34

Water Systems International has achieved what no other water filtration and sterilisation company has been able to do. After 8 years and 4 months of research and development, design, manufacture and testing we have been able to obtain NSF certification for POE (point of entry) systems, not just components.

We are the first in the world to achieve NSF 55 Class A & B, NSF 42 and NSF structural certifications on apartment, residential, commercial and marine drinking water systems.

We are now able to offer complete easy installation systems that are designed to the very highest standards made from marine grade 316L stainless steel with full all weather covers. We are now looking for international distributors.

Request more information

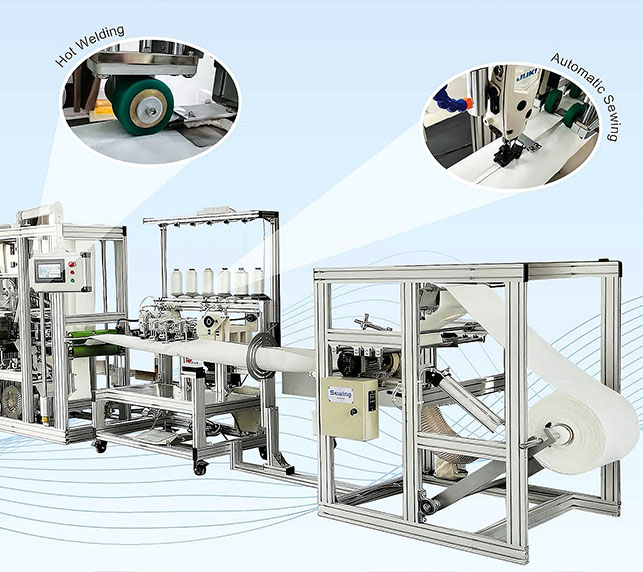

FILMEDIA Advanced Automatic Filter Bag Making Machine Line Newly Launched

FILMEDIA – Hall 7 – R35

FILMEDIA will present its Fourth Generation AUTOMATIC SEWING/ HOT WELDING/ PTFE TAPE SEALING MACHINE LINE for filter bag tubes at this year’s FILTECH. In contrary to previous versions, the surface of the filter material is flawless when stop for hot welding and PTFE tape sealing, which greatly reduces material waste. In addition, the special heating device allows the heating temperature to reach 700 degrees celsius and can be bonded to pure PTFE tape.

Main Functions:

• Automatic sewing function. Sewing speed: 4-10m/min. Sewing diameter: 120-230mm.

• Automatic hot welding function. Welding speed: 8-16m/min. Welding diameter: 90-220mm.

• Automatic PTFE taping function. PTFE taping speed: 4-10m/min. Diameter: 120-230mm.

• Automatic filter bag length cutting function. Max. Cutting length can be 12 meters.

Equipped with:

• automatic disconnection detection and automatic stopping device.

• stripping machine and film cutting collection device, high-power hot air device, high-power cutter motor and tungsten steel blade.

• needle cooling function, backlight detection function.

• alarm functions such as temperature abnormality, film shortage and abnormal filter bag length.

• JUKI brand sewing head and aluminum profile structure.

• intelligent centralized control function.

• and especially suitable for woven fiberglass filter bag and PTFE filter bag production.

BioEir Air Filters – 100% Sustainable and Biodegradable Air Filters

IREMA IRELAND – Hall 8 – F54

BioEir is the first commercially available fully sustainable and biodegradable filter media. Manufactured in our facility in Limerick, Ireland – BioEir has already been installed in several data centre AHU sites. This has already demonstrated its capabilities in reducing energy use and increasing filter replacement intervals, resulting in overall cost savings for customers.

BioEir is also being considered for large scale use in several exciting projects across residential, industrial and commercial sectors in several markets as the demand for more sustainable solutions increases.

For more info visit us in Hall 8/F54!

Request more information

LENSER i-Plate revolutionizes filtration processes

LENSER – Hall 8 – F42

The LENSER i-Plate significantly enhances efficiency and control in filtration processes. This innovative solution enables real-time measurements directly from the filter press – a profound optimization of the process.

In a time where process monitoring is crucial, the LENSER i-Plate sets new standards. With an integrated sensor capturing moisture, temperature, and electrical conductivity in the filter cake, it significantly shortens the conventional iterative process of filtration optimization. This leads to a significant increase in production capacity and substantial savings in energy and water consumption.

Through precise tracking and control of the entire filtration cycle in real-time, the LENSER i-Plate allows for targeted adjustment of each step. This means that companies are now able to define and control the ideal filling cutoff point for various suspension qualities in real-time. Additionally, it enables the early detection of the optimal end of the pressing duration.

To facilitate customer access to this new technology, LENSER offers an exclusive leasing option for the digital sensor to interested parties of the Basic and Visual service packages. This enables companies to optimize their filtration process without major investments. Also, for customers who only need insights into the drainage behavior of their filtration environment for a limited period, LENSER’s Rent-Your-Success is very attractive: They can lease the sensor with a monthly cancelable usage agreement.

To benefit from the advantages of the LENSER i-Plate, the purchase of a customized LENSER filter element into which the sensor is embedded is a prerequisite. The duration of the usage agreement is between three and 24 months, after which the user can purchase the sensor. Alternatively, the agreement can be terminated prematurely, with a special PP dummy placed at the sensor’s position, which is then returned to LENSER.

Request more information

Discover Confidence in Respirator Integrity with the Respirator Leak Tester 8119A

TSI – Hall 8 – E37

Whether in healthcare, industry, or any PPE-required environment, the quality of your respiratory protection equipment cannot be compromised. The 8119A, compatible with the Automated Filter Tester 8130A, ensures safety and effectiveness by testing various components like eyepieces, valves, and cartridges.

This duo empowers critical post-maintenance tests or whenever doubts arise, ensuring that your respiratory protection equipment consistently meets the highest standards of safety and effectiveness. A legacy continues with the 8119A, the successor to the original 8119 accessory. Trust its evolution for advancement, precision, and reliability.

When it comes to safety, equip your 8130A with the 8119A for peace of mind. Don’t compromise on safety; make sure your masks are in proper physical condition with this new Respirator Leak Tester.

Learn more: https://tsi.news/4cZQ3wq

Filter Testing Instruments from TSI®

At TSI, we are committed to providing you with the highest quality filter testing devices and support. Contact us today to learn more about our products and how we can help you ensure occupational health and safety with confidence.

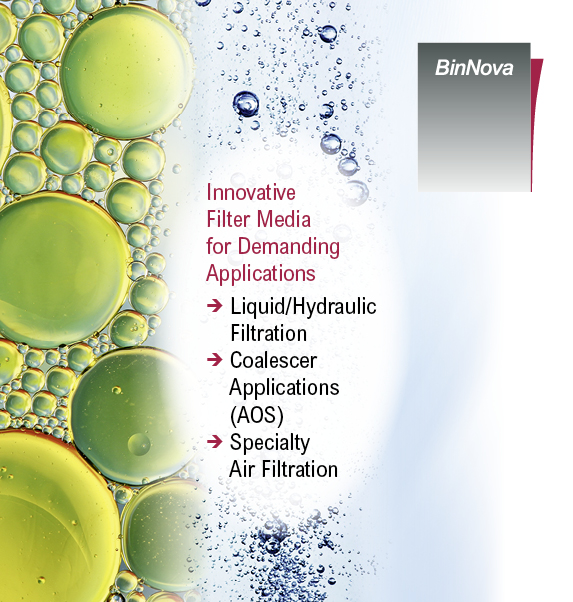

BinNova presents three new exciting filter media products

BinNova – Hall 7 – R7

High-Capacity Liquid Filtration Media

“BinNova is the technology leader for high-capacity materials for liquid filtration. At a given efficiency these materials provide highest permeability, lowest pressure drop and at the same time best dirt holding capacity.

The difference to conventional materials is significant. In many applications it is possible to replace a pre-filter layer and a main filter layer with one HC layer only.”

FC6-free Air-Oil-Separation Coalescer Media

“BinNova is setting a new standard for environmentally conscious and high-performance filtration. Choose sustainability without compromising efficiency – FC6 free media ensures exceptional liquid- aerosol separation in gas streams without the use of fluorocarbons, contributing to a greener and cleaner industrial operation.”

Multi Layer Composites

“BinNova offers a broad range of composite filter materials for a lean filter manufacturing process compared to traditional Co-Pleating. BinNova provides synchronized rolls in width and length for better logistics and significantly reduced material wastage.”

Request more information

1A Star presents: 100% electrical cutting press

1A Star technische Kunststoffe GmbH – Hall 8 – F30

1A Star is delighted to present its new 100% electrical cutting press at FILTECH 2024! This innovation allows the operator to place his cutting tool and freely remove the cut parts.

When necessary and as an option, the tool can be placed under the bridge. In this case, the operator recovers only the cut parts. In other words, on this machine, the cutting counterparts can be located both on the bridge and on the rising table.

Bridge recoil is adjustable on the touchscreen in 100mm increments (configurable).

The table rises vertically towards the receding head when it is in the forward position.

The machine is easy to use thanks to its intuitive tactile interface.

Energy savings, easy to use, high productivity, minimum maintenance and safety are the key words used to define this cutting press.

Request more information

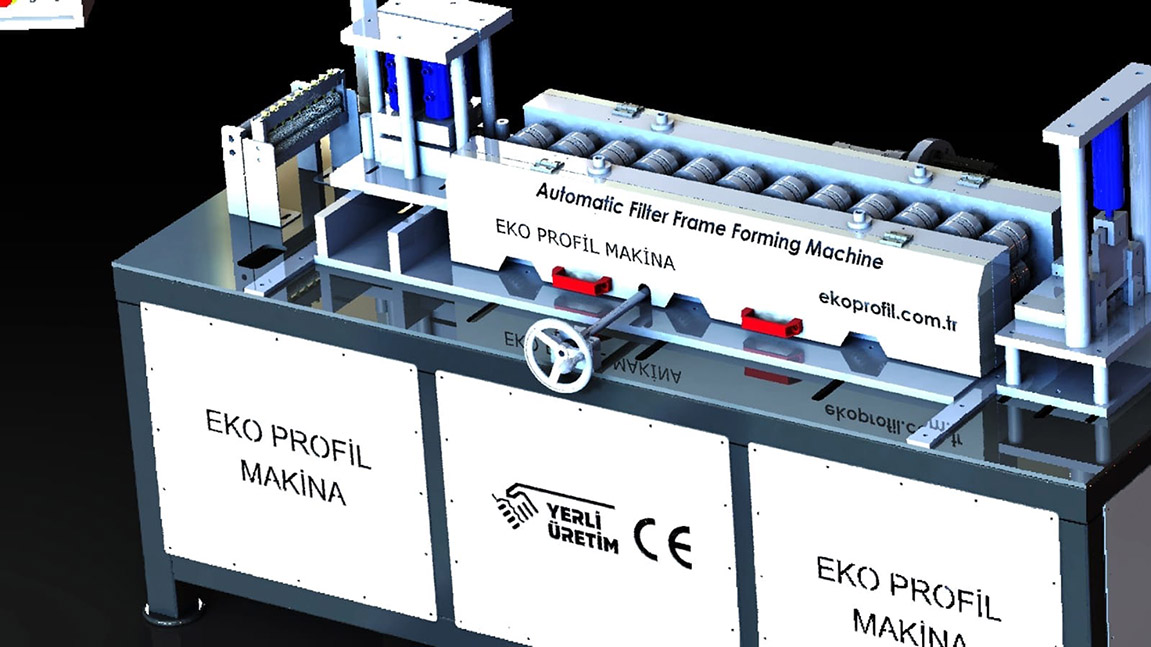

2024 NEW Filter Frame Forming Machine

EKO PROFİL MAKİNA SİSTEMLERİ – Hall 8 – A13

Eko Profil Makina Systems will present its newest Innovation at the 2024 FILTECH Show:

A new Filter Frame Forming Machine which excels in Cassette- and Bag Filters’ outer frame production.

This new, highly specialized machine has a width adjustable body and is able to produce all widths from 20mm to 100mm.

KFK-E POWER

Maschinenfabrik Herbert Meyer – Hall 8 – C47

#faster #precise #hotter

MEYER developed a special edition of the most successful Flatbed Laminator KFK-E with some remarkable new features. The new KFK-E Power. More precision, more power, higher productivity and equipped with new belts for higher temperatures, while keeping a compact design. This machine is fully capable of processing filter media!

#FASTER:

• 100% stronger Heating zone

• Faster heat up time

• Faster production speed possible

• Power level can be reduced, if not needed

• 400% more cooling capacity, reducable

#PRECISE:

• Independent level & pressure adjustment for left and right side of pressure roller

• Level can be adjusted within 0,02mm compared to 0,1mm in standard KFK-E

• Very useful feature for calibration tasks, where materials are thermo-calibrated to a certain thickness

#HOTTER:

• New endless belt technology for higher temperatures and mark free production

• PTFE coated glass fabric belts, truly endless, without marking of a seam

• Temperatures up to 290°C possible. (Some restrictions apply)

From particles to molecules - New air filter test systems according to ISO 29463 and ISO 10121

Topas GmbH – Hall 8 – E76

Topas is going ahead proving its core competence in air filter testing equipment.

After more than 90 global installations of HEPA and ULPA filter scanners according to EN 1822 and ISO 29463 using x-y traverse systems a new technology for 3-dimensional filter scanning has been developed. This enables leak detection and determination of local filtration efficiencies also at filter cartridges and V-shaped filters. There is almost now limit regarding 3d filter geometries since all required PLC and software programming is done in-house.

A second key project is related to molecular testing of adsorptive HVAC filters according to new ISO 10121 standard. We look back to a long history in molecular filter testing starting in 1998. Based on our experience, skills, and technical creativity we will now design a first commercial test setup for one of our long-term key customers.

There are certain test gas generation and measurement technology synergies that will be applied from a current project on fuel cell intake filters.

Good to know: Our Technical Innovation Center will be available for doing your own filter tests.

Request more information

IT for Engineering (it4e) GmbH is your partner for digitalizing especially fluid and particle processes.

IT for Engineering (it4e) – Hall 8 – C28

With our simulation software DNSlab, you can generate models of porous filter media, calculate permeabilities, filtration efficiencies and lots more. DNSlab combines Computational Fluid Dynamics (CFD) with the Discrete Element Method (DEM). DNSlab novelties in 2024 are:

• increased CFD performance: analyze bigger 3D models with same memory

• improved models for CFD-DEM coupling: switch between hard sphere and soft sphere contact model

• new Python interface: integrate DNSlab computations in your python environment

The new Python interface enables you to customize the DNSlab pre- and postprocessing. You can now calculate fluid and particle flow with DNSlab through self-generated 3D models and analyze the results via python code. This enables faster integration of DNSlab in your individual simulation environment.

Request more information

Ultra High Activity Coconut Activated Carbon for VOC and Air Treatment Applications

Elite Carbon Creations Private Limited – Hall 7 – H13

Elite Carbon Creations Private Limited is delighted to present a new product: Ultra High Activity Coconut Activated Carbon for VOC and Air Treatment Applications. 140 CTC or 1800 Iodine number Activated carbon with Single pass.

Request more information

High Capacity Large Capsule Filter Provides Flexibility, Convenience And Excellent Filtration Performance In Small And Medium Scale Applications

TS Filter - Precision Filter Materials – Hall 7 – R16

Large capsule filter consists of a standard cartridge encapsulated in a robust polypropylene housing, is available with TS Filter’s full range of filter media for filter cartridges, this ready to use disposable capsule filter is available in T-type, A-type and inline configurations in lengths up to 40 inches, with inlet and outlet connections including sanitary flange and hose barb, is the best solution as a scale up filter for pilot and production scale processing in pharmaceutical, food & beverage and electronics industries.

FEATURES AND BENEFITS

- T-type, Inline, and A-type capsule designs, A-type capsule includes a gauge port for pressure measurement and a filter stand for fast and easy installation

- 10”, 20”, 30”, 40” lengths

- Removal ratings from 0.04 µm to 100 µm

- Low hold-up volume and production losses

- Without the need of a stainless filter housing

- Protects operators during setup, production and cleaning

- Easy to use, rapid installation and minimum downtime

- Robust construction stand up to autoclave sterilization

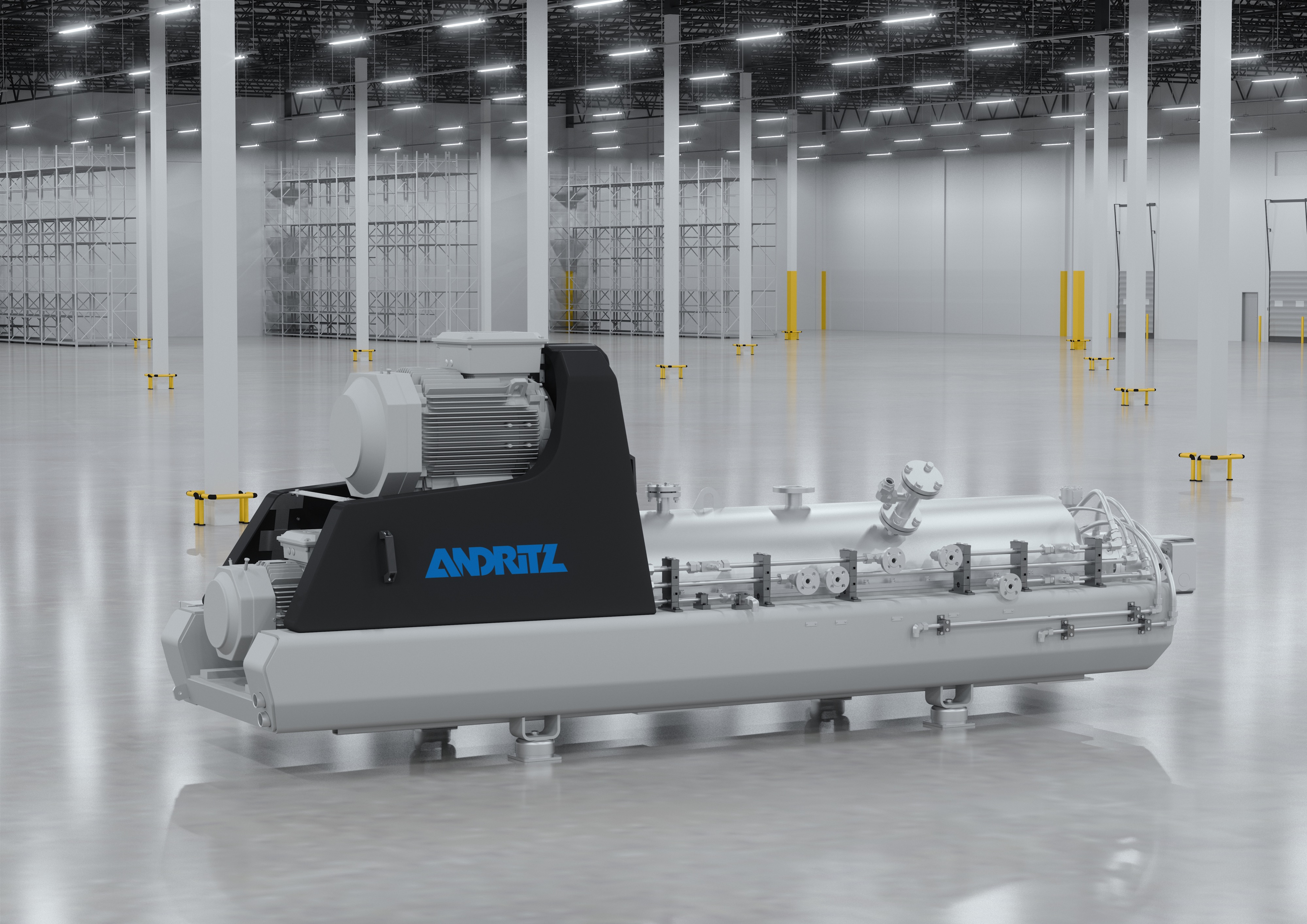

ANDRITZ introduces decanter centrifuges tailored to challenging industrial oil recovery, for use in both ATEX Zone 1 and 2 areas

ANDRITZ Separation GmbH – Hall 8 – F42

ANDRITZ 3-phase decanter centrifuges are not only capable of separating liquid from solid but also liquids with different densities like oil and water. These proven machines have now been further developed and tailored to the recovery of high purity oil from tainted sources such as slop and crude oil, lake, lagoon or tank cleaning and API separator sludge. This is part of ANDRITZ’s commitment to conserve resources and protect the environment in partnership with its customers.

Crucially for oil and gas applications, the ANDRITZ decanter centrifuge range includes now both ATEX Zone 1 and Zone 2 machines. This makes them suitable for use in plants where an explosive atmosphere may occur during normal operations. Machine housing seals can be supplied as gas-tight, flame and explosion-proof versions. And many other technical innovations make this machine highly reliable for industrial process.

The latest additions to the ANDRITZ decanter centrifuge range build on more than a century of expertise with more than 30,000 references worldwide and a global network of support and manufacturing infrastructure.

Request more information

New 30 & 60 liter tank melter PH30 & PH60

Puffe Engineering – Hall 8 – A24

New 30 & 60 liter tank melter PH30 & PH60

Due to decades of experience in hot-melt adhesive technology Puffe Engineering is a reliable partner and provider for tailor-made solutions in many industries.

In 2024 we are launching our latest PH30 & PH60 tank melters with Siemens S7 PLC control, integrated heating register and pull-out control cabinet. This allows easy access to the pump(s) & electric motor for easier service. Both variants will be available with 2 single gear pumps, 2 PowerFoam pumps or with a double gear pump, with up to 2 outputs.

The new tank melters of Puffe Engineering are made from high quality components. The aluminum milled main melt from a block ensures better temperature transfer to the material and at the same time better temperature storage. Another plus point are the removable pre melt register and the bayonet removable filters.

Our tank melters are extremely durable and robust, even when used at extremely high temperatures. If desired, you can choose between a solid and a PowerFoam® optimized application.

The new melters are also perfectly matched to our parts, like our hoses, application heads and modules.

Request more information

needlona® BLUE - the filter medium for a reduced CO2 footprint

BWF Envirotec – Hall 8 – B11

Our new needlona® BLUE product line is the environmentally friendly filter medium with which we already achieve more than 10% CO2 savings in the manufacturing process compared to a standard filter medium. This is how we put our climate protection measures into practice. For a clean environment of the future.

needlona® BLUE is environmentally friendly and energy efficient thanks to

- increased use of high quality, recycled fibres

- own in-house recycling

- optimised use of operating resources in the production

Calculation and certification by ClimatePartner

The Product Carbon Footprint calculation is based on the GHG (Greenhouse Gas) Protocol. It records the CO2 emissions of needlona® BLUE in the individual phases of the product life cycle. This takes raw materials, manufacturing, transport and waste disposal into consideration.

Filter bags which are already environmentally friendly in the manufacturing process thanks to a reduced CO2 carbon footprint.

For further details on filtration solutions using needlona® BLUE contact our Sales at sales_at_bwf-envirotec.com

Request more information

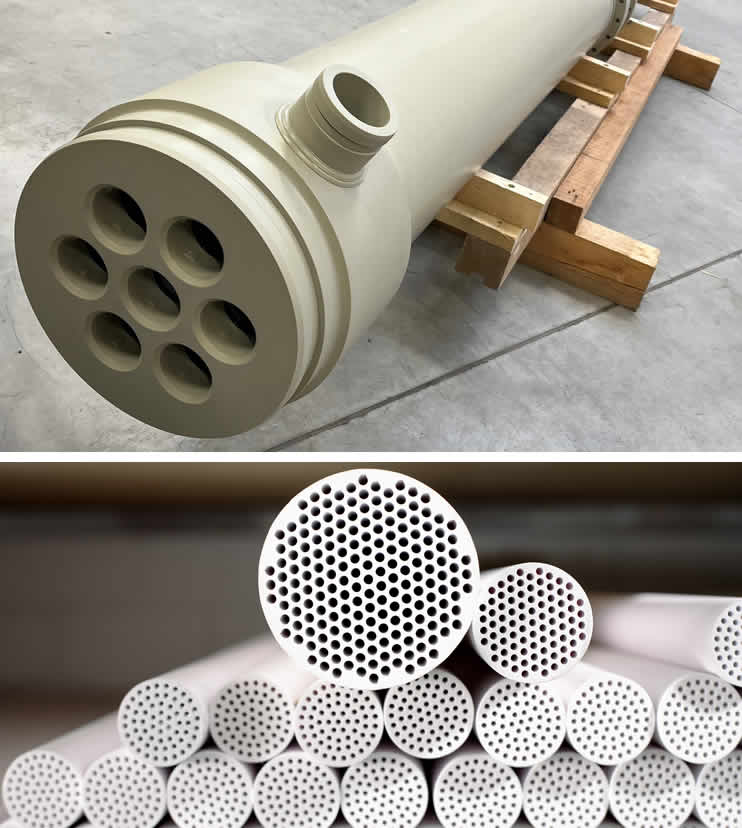

atech Ceramics in Polypropylene (PP) housings

atech innovations gmbh – Hall 8 – D18

Since end of 2021 the major producer of polypropylene membranes has stopped his manufacturing for tubular PP membranes.

As a consequence of this termination, PP modules like “Microdyn® tubular modules” or “T-cut-PP” are no longer available, thus membrane system operators are facing a problem if it comes to membrane replacement.

atech innovations gmbh has developed a housing made of polypropylene with exactly the same dimension as the a.m. PP modules but equipped with their unique ceramic membranes in 1,5 µm length (the photo shows a module with 3 m length, for total of 14 membranes).

Just by adapting the individual connections (feed/retentate/permeate), the atech PP modules fit into the PP- membrane system without further modification.

The atech PP-housing does not have any metal parts (fully PP design) so it can be used for corrosive applications as well.

Key features of atech PP module with ceramic membranes:

• pore sizes available from 1,2 µm to 1 kD (including 0,2 µm)

• narrow pore size distribution

• channel diameter 4 mm (5,5 in preparation)

• filter surface (up to 18m²), can be adapted

• similar feed flow rates as PP membranes (no pump modification necessary)

• membranes can be exchanged separately without change of housing

• can be used for corrosive liquids (no metal parts in contact with liquid)

• high chemical resistance

• extremely high water permeability

91XFP Pleat Forming Machine

SPM srl – Hall 8 – A26

Spm continues the development and research of technical solutions, aimed at satisfying the growing automation and customization needs linked to the different stages of the production process in the field of filtration.

This goal led to the creation of the new 91XFP Pleat Forming, machine for processing the filter media, with longitudinal pre-cutting device and automatic deposit of glue lines. This process recreates the pleat and allows to obtain the spacing of the pleat itself or spaced elements with sealed edges.

Combined with a pleating machine with blades or rollers and a transversal cutting device, the complete filter production line is created.

Request more information

Breakthrough for heated gas filtration up to 800 °C with HJS Sintered Metal Technology SMF

HJS Emission Technology GmbH & Co. KG – Hall 8 – D22

HJS from Menden, Germany, is a global leader in providing a revolutionary approach to emission reduction through its leading-edge sintered metal filter technology – SMF.

SMF filters are manufactured using expanded metal. The coil band configuration has a 0.38 mm cross-section and offers a 99 % filtration efficiency with the ability to remove particles < 5 μm.

Its exceptional temperature resistance up to 800 °C / 1.500 ° F allows for a broad range of high-temperature applications and provides enormous potential for energy reduction e.g in bag house filter applications.

“Utilizing technical ingenuity and experience for new industrial applications in Hot Gas/Liquid and Process”

Request more information

Roth Composite Machinery presents innovative length cutting system

Roth Composite Machinery GmbH – Hall 8 – A21

Roth Composite Machinery will present an innovative, swivelling length cutting system for its knife pleating machines for the production of filters for the first time. These filters are used in a wide range of applications.

The new length cutting system enables an increase in production output, as the maximum width of the filter material is fed into the machine and the filters are cut through in individual widths lengthwise to the material web. The machine design developed by Roth Composite Machinery features the length cutter directly in front of the folding knives. “For safety and ergonomic reasons, we have designed the complete infeed table, including the cutter, to swivel. The operator can swivel the table by 90° in a position provided for this purpose, so that the cutter practically swings out of the machine. The swivel position is deliberately chosen at the centre of gravity of the infeed table so that the swivelling process can be carried out easily,” explains Winfried Schäfer, Senior Sales Manager at Roth Composite Machinery. The operator can make the necessary adjustments on the length cutter directly and without physical exertion.

For better and risk-free handling in the production process, Roth Composite Machinery has further developed the positioning of the cutting system in the machine.

Request more information

ContiLoop: Single-use multicycle filter for process intensification

DrM Dr. Müller AG – Hall 8 – E46

The ContiLoop is the most sophisticated single-use cyclical cake filtration technology available worldwide. The operation of the filter in cycles, allows for back flush capabilities and filter cloth regeneration, a unique way to evade clogging and cloth fouling. The filter bag and manifold can easily and safely be assembled and dissembled following instructions given by the control panel. The cyclical nature allows the user to combine all the benefits of disposable technology while also prolonging the lifespan of one filter cloth.

The Key Benefits of ContiLoop include:

• Very high filtration rate (2-3x higher than depth filters)

• High filtrate quality (on par with depth filters)

• Increased yield in cell recovery and enzyme recovery operations

• Shorter reactor downtime due to reduced cleaning & validation requirements

• Pre-sterilized and validated filter enclosure available for Pharma and Biotech applications

• Reduced heel volume and compaction of solid waste

• Fully enclosed containment made completely of plastics ensuring safe handling and disposal of hazardous components

• Available in 3 sizes

Visit our booth at the event or contact us for optimized filtration and mixing solutions.

Request more information

New antimicrobial technology AGXX® to prevent microbial contamination and biofouling in water filtration

Heraeus Precious Metals – Hall 7 – M11

Water filters are prone to contamination by microorganisms and biofouling endangering not only consumer health but also shortening product lifetimes. Particularly in the light of the spread of multi-resistant germs, it is more crucial than ever to protect filters from bacterial growth and to enhance water quality by innovative antimicrobial technologies.

AGXX is a new antimicrobial technology which is based on generation of reactive oxygen species (ROS) from water and oxygen by a catalytical reaction supported by two precious metals. AGXX is not based on the release of metals into the environment and offers long-lasting protection. The technology can already be used today in accordance with the Biocidal Product Regulation (BPR). To this date, it has shown antimicrobial efficacy against over 130 microorganisms including bacteria, viruses, algae, and fungi, among others silver-resistant E. coli strains, methicilin-resistant S.aureus (MRSA), or CoV2 viruses.

The technology is available in various product forms, including activated carbon powders, granules, or pellets as well as on inorganic carriers for incorporation into textile filters.

Request more information

Jowat Adhesives for Filter Manufacturing - Environment-Friendly - Sustainable - Safe

Jowat SE – Hall 8 – B8

Jowatherm-Reaktant® MR – Powerful and Hazard-Free

The new Jowatherm-Reaktant® MR 614.50 provides very good results with a low application amount in the lamination processes of activated carbon filters as well as multi-layer filter media. It can be processed at temperatures 40–50°C lower compared to the PUR hot melt adhesives currently on the market—this saves resources and facilitates an optimized application process.

Adhesives from the Jowatherm-Reaktant® MR product range (MR = monomer-reduced) have a free monomeric isocyanate content of less than 0.1%. In accordance with the current EU regulation, the adhesive is therefore not subject to hazard labeling requirements.

Request more information

Classification, Clarification, Concentration - Versatile, new process solutions by the use of metallic filter media in dynamic crossflow filtration

BOKELA GmbH – Hall 8 – A45

The use of metallic filter media in dynamic crossflow filtration with BoCross filters enables versatile and completely new process solutions for tasks such as classifying, clarifying liquids and concentrating solids.

For such tasks the use of metallic filter media offers solutions tailored to the product and objective when state-of-the-art technologies such as wedge wire screen, candle filters, backflush filters, vibration screens, centrifuges or membrane filters reach their limits. Innovative processes such as dynamic sieve filtration and dynamic precoat filtration can be realised. Dynamic sieve filtration allows to continuously sieve out disruptive coarse particles from highly concentrated or highly viscous suspensions with a sharp separation cut. Dynamic precoat filtration allows to completely separate solids and thus produce absolutely clear filtrates. Thereby, the ground layer is created by particles of the suspension – without addition of other substances. Also microfine suspensions can be concentrated when the use of microporous membranes (polymeric or ceramic) is not possible. The modular design of the BoCross filter – i.e. the series arrangement of the filter elements – is a great advantage in this regard. Adaptation to the different separation tasks is done by varying various parameters.

Request more information

NEW innovative material - Sustainable bio-based filter frames

MÖLLER GmbH & Co. KG – Hall 8 – A15

MÖLLER is the leading manufacturer of plastic filter frame systems with 75 years of history and experience.

We offer a full line of frame components for almost every filter application and can provide customized options to meet any customer’s specific need.

MÖLLER goes GREEN

We are aware of the increasing importance of environmental protection and want to make our contribution to a sustainable air filter.

Therefore, we have developed filter frames made of a completely bio-based material. This new innovative and sustainable material does not contain any fossil components.

MATEC Twin Frecciarossa Filter Press: Highest productivity with a proctective shell for harsh environments

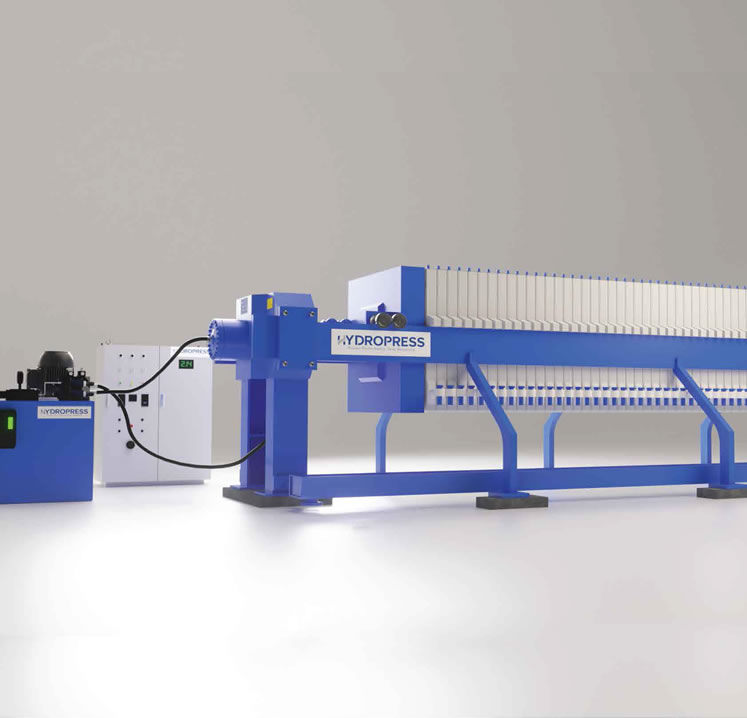

MATEC – Hall 8 – C4

Matec industries has engineered the world’s first filter press capable of meeting the highest demands in the recovery of materials from different sectors, combining the efficiency of two machines into a single product with extraordinary performance.

The Twin frecciarossa is currently the most productive filter press on the world market, in terms of operating time and the amount of sludge to be treated. It is also optimized from the point of view of production effectively doubling the market standards. This filter press is also economically optimized, reducing the cost of the structures and engineering works necessary for operation.

The Twin frecciarossa can be equipped with a protective shell (optional), available for all the filter press range. A solution to protect the oleodynamic group and pistons in particularly harsh environments.

Request more information

Digital design and virtual switching of cartridges to increase filter performance – the new GeoDict software feature

MATH2MARKET GmbH – Hall 7 – M28

Computer-Aided-Design (CAD) is of keen interest to simulate flow and filtration on filters with cartridges. However, performing systematic simulations on different geometrical setups requires the generation of these structures as CAD individually and the import of each sample separately.

A new feature in the GeoDict software allows to generate a variety of cartridges with changing pleat count, pleat thickness, and number of porous layers, and digitally switch them inside the housing. Starting now, it is easy and quick to find the ideal configuration between filter area and pleat count for cartridges and their housing, regarding their local minimum pressure drop and many filtration relevant parameters.

This digital test of the performance of filter prototypes circumvents the need for expensive, trial-and-error manufacturing and testing phases, since only promising prototypes undergo measurements at the testbench. These systematic simulations with varying geometries or flow rates may be run simultaneously in cloud applications to further increase the productivity, fit customers requests, and decrease time-to-market.

Request more information